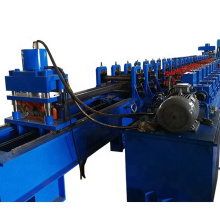

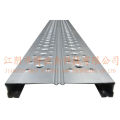

Marine Steel Scaffolding Planks Board Walkboard Roll Forming Production Machine

Basic Info

Model No.: BOSJ-F

Product Description

Model NO.: BOSJ-F Forging Forming Method: Free Forging Feature: Automation Warranty: 12 Months Advantage: Easy to Maintenance Brand Name: Bosj Control Type: Auto Trademark: BOSJ HS Code: 8455212000 Type: Rolling Machine Power Source: Hydraulic Pressure Certification: SGS, ISO9001 Customized: Customized Condition: New After-Sales Service Provided: Overseas Service Center Available Control System: PLC Control System Origin: Jaingsu China Marine Steel Scaffolding Planks Board Walkboard Roll Forming

Machine

1,Unit performance

The thickness of material sheet: 1.2-1.8,the product drawings need to be confirmed by buyer

The width of material: 250≤§≤520

Product speed: 0-8m/min

Occupy groud area: length 30m xwidth 3m

Total power: about 62kw

2,Equipment structure

It is composed of passived-decoiler, leveler, servo feeding machine, punching machine, roll forming machine, hydraulic cutting machine, collection table, electrical control system etc.

3,Each part main parameter:

3,1 Passived Decoiler

Decoiler: decoiler, Inner expanding type, capacity:5T

Inner diameter material roll: ¢480~¢520mm

Outter diameter material roll: ≤1500mm

3,2 Leveler

Motor: 7.5KW Frequency conversion motor

3,3 Servo Feeding machine

Drive: 4 kw Servo motor

3,4 Punching machine

punching press: JF21-110

Maximum press: 110tons

Material of mould: Material:Cr12Mov, Quenching,Hardness:HRC58-62º

Quantity of punching dies:1sets

3,5 Forming machine

Rack: cast iron frame,

Forming stations: 16 stations

Material of bearing 40Cr, quenching treatment

Material:GCr15, Quenching, Hardness:HRC58-62º

Motor power: 30KW Frequency conversion motor ZQ500 reducer

Drive type: every rack has one gear power distribution box.

3,6 Hydraulic cutting

Hydraulic pressure cutting

Hydraulic pressure pump:5.5KW

Material of cutting blade: Cr12, Quenching

Hydraulic cutting quantity:1piece

3,7 Electronic controlling: PLC

Main Machine Parameter

Delivery of machine

Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roll Forming、Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roll Forming、Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Machine

1,Unit performance

The thickness of material sheet: 1.2-1.8,the product drawings need to be confirmed by buyer

The width of material: 250≤§≤520

Product speed: 0-8m/min

Occupy groud area: length 30m xwidth 3m

Total power: about 62kw

2,Equipment structure

It is composed of passived-decoiler, leveler, servo feeding machine, punching machine, roll forming machine, hydraulic cutting machine, collection table, electrical control system etc.

3,Each part main parameter:

3,1 Passived Decoiler

Decoiler: decoiler, Inner expanding type, capacity:5T

Inner diameter material roll: ¢480~¢520mm

Outter diameter material roll: ≤1500mm

3,2 Leveler

Motor: 7.5KW Frequency conversion motor

3,3 Servo Feeding machine

Drive: 4 kw Servo motor

3,4 Punching machine

punching press: JF21-110

Maximum press: 110tons

Material of mould: Material:Cr12Mov, Quenching,Hardness:HRC58-62º

Quantity of punching dies:1sets

3,5 Forming machine

Rack: cast iron frame,

Forming stations: 16 stations

Material of bearing 40Cr, quenching treatment

Material:GCr15, Quenching, Hardness:HRC58-62º

Motor power: 30KW Frequency conversion motor ZQ500 reducer

Drive type: every rack has one gear power distribution box.

3,6 Hydraulic cutting

Hydraulic pressure cutting

Hydraulic pressure pump:5.5KW

Material of cutting blade: Cr12, Quenching

Hydraulic cutting quantity:1piece

3,7 Electronic controlling: PLC

Main Machine Parameter

| No. | Item | Unit | Data | Remark | |

| 1 | Raw material | Type | MS\galvanized sheet | ||

| Strength of panel | Map | ≥350 | |||

| Thickness of panel | mm | 1.2~2.0 | |||

| 2 | Size | mm | See figure | ||

| 3 | Speed | m/min | 6~8 | ||

| 4 | Material of roller | GCr15Hardening treatment | |||

| 5 | Drive type | Gear box | |||

| 6 | Total power | kw | About 45 | ||

| 7 | Electrical system | PLC Inverter control | |||

| 8 | Contour dimension(L*W*H) | m | 35X4X3.9 | ||

Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roll Forming、Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roll Forming、Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Scaffolding Planks Roll Forming Machine

Premium Related Products

Other Products

Hot Products

Support Steel Post for Grape Garden Roll Forming Machine Supplier AustraliaInternal Combustion Engine Turbocharger Compressor Wheel TurbobilletCustomized Pre-Galvanized Scaffold Foot Planks Scaffolding SystemGalvanized Solar Stand Roll Forming Machine Manufacturer for Saudi AabiaAuto China CNC Plasma Cutting Machine for RussiaAuto Car Collision Beam Roll Forming Machine Maunfacturer DubaiAuto China Cable Tank Ladder Roll Forming MachineSupermarket Steel Shelf Storage Deck Panel Roll Forming MachineMsfd VCD HVAC Fire Damper Shutter Frame Blade Louver Roll Forming MachineMarine Steel Scaffolding Planks Board Walkboard Roll Forming Production MachineAuto Steel Silo Corrugated Sheet Roll Forming Machine-BosjAuto Swisss Electric Cabinet Purlin Roll Forming Machine (BOSJ)Two Thire Waves W-Beam Highway Guardrail Roll Forming (BOSJ)C/Z/U/Omiga Purlin Exchange Roll Forming (BOSJ03)Steel Scaffolding Planks Board Roll Forming Line Manufacturer MalaysiaAutomatic Galvanized Steel Cable Tray Cold Roll Forming Machine (BOSJ)