Aluminum roll forming machine for the production of corrugated metal

Product Description

Aluminum Roll Forming Machine for the production of corrugated metal

This Corrugated Roofing Sheet Forming Machines are for the manufacture of Metal corrugated Roof sheets and Siding Panel. Our corrugated roofing sheet Forming Machine are special for manufacturing various high quality roof & wall cladding. With our engineer's many times improvements, the roof machine design is perfect. The profile surface is smooth and power fee is lower, driven by chain. The whole line consists of uncoiler and its base, coil sheet guiding equipment, roll forming system, post-cutting equipment, hydraulic station, controlling system, and run out table.

Further information, pls contact with us!

| Product name | TR4 roof sheet roll forming machine maquina para fabricar tr4 | |||

| NO. | Items | Parameters | Remark | |

| 1 | Suitable Material | Type | GI/PPGI/AL | |

| Width | 1000/1200/1220/1250mm | Custom | ||

| Thickness | 0.30-0.80mm | |||

| 2 | Product Specifications | Length | Any length | |

| Length Tolerance | ±2mm/6m | |||

| 3 | Working Speed | 25 m/min (10 piece per min as 8 feet per piece) | Standard machine | |

| 4 | Control System | Mitsubishi/Siemens PLC& transducer | Custom | |

| 5 | Total Power | About 11KW | ||

| 6 | Total Weight | About 7T | Up to final design | |

Technical Parameters for Corrugated Sheet Forming Machine:

Material width: 1220 and 1000mm.

The thickness of Coil: 0.2mm-0.8mm.

Application: Wall sheet and roof sheet

The overall dimensions: 8600mmX1500mmX1300mm

Total weight: 8T

Main Power: 11 KW.

The main parts of Corrugated Sheet Forming Machine:

Manual Uncoiler 1 set

Feeding Guider 1 unit

Roll forming machine 1 set

Hydraulic Cutting system 1 unit

PLC Control System 1 unit

Product Rack 2 PCS

Introductions Of the Corrugated Sheet Forming Machine Parts:

Uncoiler: Manual uncoiler

Inner diameter: 508mm

Outer diameter: 1500mm

Coil Width: 1220mm and 1000mm.

Material Thickness: 0.2mm_0.8mm

Loading weight: 5 Tons

Corrugated Sheet Forming Machine

Forming speed: 10-25m/min

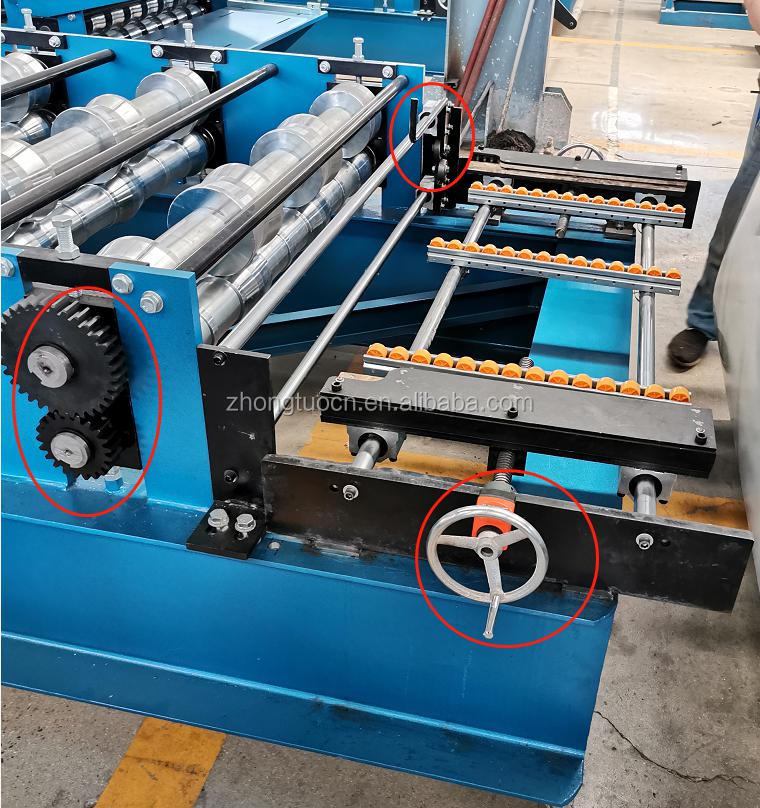

Forming stations: 18 stations

Construction Structure: Welded with 300 # H-steel

Material of Shafts: 45# steel with rough finished and then refined finished.

Diameter of the shafts: 80mm

Material of Rollers: High quality 45#steel coated with hard chromium 3mm

Processing Technology: Rough processing ---refined processing--Hard Chromium Plating.

Material of Rack: Complete welded structure of A3 steel plate 20mm thickness.

Transmission: Transmitted by the chain and gear.

Material of Chain: 45#steel with heat treatment of HRC45-50°

Main Power: 7.5KW.

Hydrualic Cutting of Corrugated Sheet Forming Machine Line:

Material of cutting blade: Cr12 with quenched treatment 60-62

Hydraulic Power: 5.5KW.

Cutting Length and Quantity: Clients can set the required length and quantity on the PLC touch screen

Control System: Panasonic PLC Control, LCD screen, touch screen, frequency converter

Voltage: 380V/50Hz/3phase OR based on required standard.

Automatically measure the length and quantity

Machine pictures of Aluminum roll forming machine

1. How to get a quotation?

a.Give me the profile drawing and thickness,this is the important.

b.Other spicific requirements is welcome,such as the speed,power and voltage you want.

c. If you don't have your own profile drawing, we can recommend some model types according to your local market standard.

2. Terms of payment:

30% advance payment first by T/T, Balance will be paid before shipping after inspection.

The balance payment can be paid by LC, and we can accept the full payment by LC also.

Meanwhile, we can ship the machine to you without balance payment. You can pay us the balance payment till you receive the machine.

3. Are you trade company or factory?

We are the one based on factory and international trade, we have our own design concept for the machines and have optional solutions for machine concept according the customer's request.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send new to replace for

free,but you need to pay the express cost yourself.after warranty period,we can negotiate to solve the problems, we supply the technical support for the whole life of the equipment.

1. We can give you the guarantee by money, you can take the machine first without balance and try the quality. Meanwhile, can help customer solve the fund issue.

2. Because the machine is customized, the customers will provide us the profile drawing by themselves. But some customers don't have such profile drawings, then we can recommend the model types according to the local market standard.

3. We can operate the machine with material before the customer put order if you come to my factory.

4. Both the sale person and technician can give you the service overseas and make training for the workers,

the sale person can make translation, so that the installtion and training will be more clear and easily.

5. We will prepare some spare parts along with the machine, ensure our customer can solve the issue in a shortest time.

6. The machine will be tested before shipment with coil, ensure everything is ready

7. We will be at your service always, our customres can get in touch with us anytime, even have the time difference.

Product Categories : Roof/Wall panel roll forming machine

Premium Related Products