Automatic Galvanized Steel Cable Tray Cold Roll Forming Machine (BOSJ)

Basic Info

Model No.: BOSJ-C

Product Description

Model NO.: BOSJ-C Forging Forming Method: Free Forging Feature: Automation Warranty: 12 Months Advantage: Easy to Maintenance Control System: PLC Control System Material of Roller: Gcr 15 Place: Jiangsu Origin: Jiangsu Type: Rolling Machine Power Source: Hydraulic Pressure Certification: CCC, SGS, ISO9001 Customized: Customized Condition: New Production Speed: 20m/Min Control Type: Auto Trademark: BOSJ Automatic Galvanized Steel Cable Tray Cold Roll Forming Machine

1, Equipment capabilities It can according to the need to produce the steel width (60mm≤§≤860mm), many kinds of specification electric cable bridges and other structure product. Product speed by punching: 2.55m/min Continuous rollforming speed: 1015m/min Material thickness: 1~2mm Material require: Q235 cold roll steel Production line has automatic and manual two operating mode, may realize the linkage and the partition revolution work. 2, Main composition of machine This unit consists of the decoiler, ML-900 flatting, 200 punch, die, servo feeding, guider, main roll Forming Machine, follow cutting, cut-to-length part, recoiler, electrical control cabinet; etc.

3,Each part major technical parameters

3.1 Drive decoiler Material width:860mm Material weight:6000kg Material inner diameter:508mm Material outer diameter:1200mm Drive power: electromotor and speed reducer integration, 4KW frequency conversion electromotor Frame type: cantalever inner support, manual handle afterbody, pneumatic press cantalever. 3.2 Flatting Working rolls: 11 rolls, up 4/down 5, the residual 2 rolls is clamp deliver rolls. Flatting bound: material thickness 12mm, material width 100860mm Drive power: 5.5kw frequency conversion electromotor Speed reducer model: ZQ250 flatting speed:310 m/min Parenthesis up and down a pair of fortified wheel 3.3 Continual punching mould Amount: Each kind of width specification 1 set dies, total 6 sets Die require: Cr12 quench

It finishes punching and cutting in one time.

3.4 Servo feeding Device Servo electromotor power: 4.4kw Multistage type feeding, memory ten group of memory functions Man-machine contact surface numerical control system Uses Mitsubishi servometer 3.5 Holds material (use in cushion section) The roller type, the both sides have the bearing support, 3 sets, use in holding the material and under the deposited material spacing. 3.6 Guider A pair of horizontal roller and two pairs of vertical guide rolls, total 1 sets. 3.7 Main roll forming machine Type: GY180(Extra wide) Rack structure:Dragon Gate type memorial arch frame forming frame: 22 sets Forming variety: bridge frame material max width:860mm material max thickness:≤2.0mm forming width: 75-600mm forming height: 50-100mm The diameter of the roller axis: 85mm Roll mould material: Gcr15,quenching treatment:HRC58-62° Drive type:30kw frequency conversion electromotor, ZQ500 Main speed reducer Autocephaly distribute gear case 3.8 Electrical control 3.8.1 Main operation control cubicle Amount: 1 set Frequency conversion: 3sets(in main control cubicle, control decoiler, flatting and roll forming machine) PLC control: 1 set 8 inch liquid crystal touchscreens All electrical element is the Mitsubishi original installation brand 3.9.2 Assistant control cubicle Amount: 3 sets (follow decoiler, flatting, roll forming machine) Control styp: manual handle 4,Produce condition capability: about 71.5kw gas fountain: 0.9 cube/min Production land area: 33m*3m 5,Machine Parameter

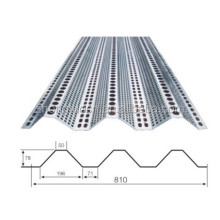

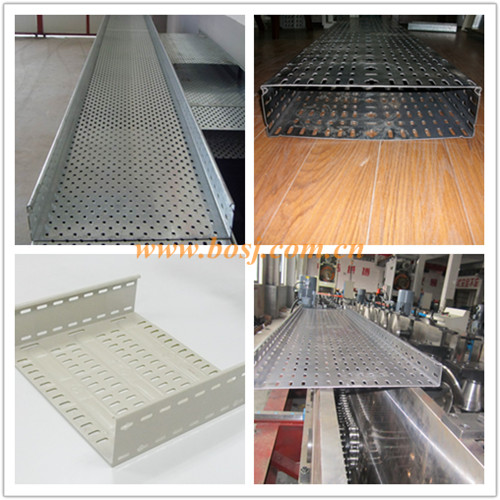

6.Cable Tray Profile

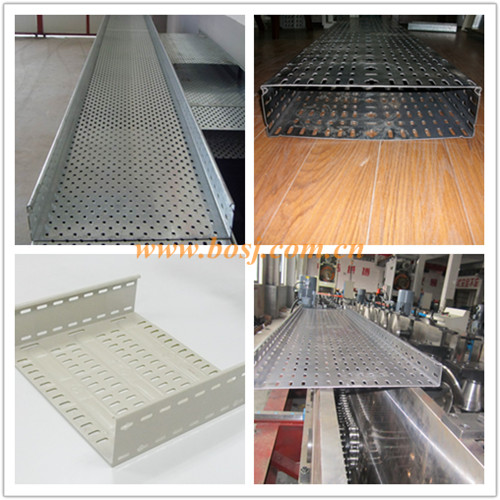

7.Delivery of Machine

Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cable Tray Roll Forming Machine、Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

1, Equipment capabilities It can according to the need to produce the steel width (60mm≤§≤860mm), many kinds of specification electric cable bridges and other structure product. Product speed by punching: 2.55m/min Continuous rollforming speed: 1015m/min Material thickness: 1~2mm Material require: Q235 cold roll steel Production line has automatic and manual two operating mode, may realize the linkage and the partition revolution work. 2, Main composition of machine This unit consists of the decoiler, ML-900 flatting, 200 punch, die, servo feeding, guider, main roll Forming Machine, follow cutting, cut-to-length part, recoiler, electrical control cabinet; etc.

3,Each part major technical parameters

3.1 Drive decoiler Material width:860mm Material weight:6000kg Material inner diameter:508mm Material outer diameter:1200mm Drive power: electromotor and speed reducer integration, 4KW frequency conversion electromotor Frame type: cantalever inner support, manual handle afterbody, pneumatic press cantalever. 3.2 Flatting Working rolls: 11 rolls, up 4/down 5, the residual 2 rolls is clamp deliver rolls. Flatting bound: material thickness 12mm, material width 100860mm Drive power: 5.5kw frequency conversion electromotor Speed reducer model: ZQ250 flatting speed:310 m/min Parenthesis up and down a pair of fortified wheel 3.3 Continual punching mould Amount: Each kind of width specification 1 set dies, total 6 sets Die require: Cr12 quench

It finishes punching and cutting in one time.

3.4 Servo feeding Device Servo electromotor power: 4.4kw Multistage type feeding, memory ten group of memory functions Man-machine contact surface numerical control system Uses Mitsubishi servometer 3.5 Holds material (use in cushion section) The roller type, the both sides have the bearing support, 3 sets, use in holding the material and under the deposited material spacing. 3.6 Guider A pair of horizontal roller and two pairs of vertical guide rolls, total 1 sets. 3.7 Main roll forming machine Type: GY180(Extra wide) Rack structure:Dragon Gate type memorial arch frame forming frame: 22 sets Forming variety: bridge frame material max width:860mm material max thickness:≤2.0mm forming width: 75-600mm forming height: 50-100mm The diameter of the roller axis: 85mm Roll mould material: Gcr15,quenching treatment:HRC58-62° Drive type:30kw frequency conversion electromotor, ZQ500 Main speed reducer Autocephaly distribute gear case 3.8 Electrical control 3.8.1 Main operation control cubicle Amount: 1 set Frequency conversion: 3sets(in main control cubicle, control decoiler, flatting and roll forming machine) PLC control: 1 set 8 inch liquid crystal touchscreens All electrical element is the Mitsubishi original installation brand 3.9.2 Assistant control cubicle Amount: 3 sets (follow decoiler, flatting, roll forming machine) Control styp: manual handle 4,Produce condition capability: about 71.5kw gas fountain: 0.9 cube/min Production land area: 33m*3m 5,Machine Parameter

| NO. | Project | Unit | Parameter | Remark | |

| 1 | Material | Type | High strength steel | ||

| Strength of material sheet | Map | ≥350 | |||

| Thickness of material sheet | mm | 1.2~2.0 | |||

| 2 | Size of production | mm | Reference the picture | ||

| 3 | Production speed | m/min | Punching speed 4m/min Forming speed 10m/min | ||

| 4 | Material of roller | GCr15 quenching treatment | |||

| 5 | Drive type | Gear | |||

| 6 | Power | kw | About 75 | ||

| 7 | Electric control system | PLC variable frequency control | |||

| 8 | Dimensions(Length*width*height) | m | 55X4X3.9 | ||

6.Cable Tray Profile

7.Delivery of Machine

Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cable Tray Roll Forming Machine、Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Cable Tray Roll Forming Machine

Premium Related Products

Other Products

Hot Products

Support Steel Post for Grape Garden Roll Forming Machine Supplier AustraliaInternal Combustion Engine Turbocharger Compressor Wheel TurbobilletCustomized Pre-Galvanized Scaffold Foot Planks Scaffolding SystemGalvanized Solar Stand Roll Forming Machine Manufacturer for Saudi AabiaAuto China CNC Plasma Cutting Machine for RussiaAuto Car Collision Beam Roll Forming Machine Maunfacturer DubaiAuto China Cable Tank Ladder Roll Forming MachineSupermarket Steel Shelf Storage Deck Panel Roll Forming MachineMsfd VCD HVAC Fire Damper Shutter Frame Blade Louver Roll Forming MachineMarine Steel Scaffolding Planks Board Walkboard Roll Forming Production MachineAuto Steel Silo Corrugated Sheet Roll Forming Machine-BosjAuto Swisss Electric Cabinet Purlin Roll Forming Machine (BOSJ)Two Thire Waves W-Beam Highway Guardrail Roll Forming (BOSJ)C/Z/U/Omiga Purlin Exchange Roll Forming (BOSJ03)Steel Scaffolding Planks Board Roll Forming Line Manufacturer MalaysiaAutomatic Galvanized Steel Cable Tray Cold Roll Forming Machine (BOSJ)