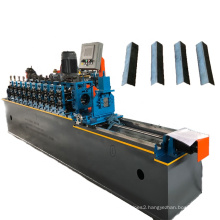

Automatic Door Frame Roll Forming Machine, Auto Msfd Frame Roll Forming Machine, Auto VCD Frame Roll Forming Machine

Basic Info

Model No.: BOSJ

Product Description

Model NO.: BOSJ Automation: Automatic Processing: Brick Cutting Machine Product: Composite Material Condition: New Type: Concrete Iron Connection Machinery Trademark: BOSJ HS Code: 8455212000 Automatic Grade: Automatic Brick Raw Material: Cement Method: Vacuum Extruder Tolerance: 0.5mm Certification: ISO9001: 2000 Control System: PLC Control System Origin: Jiangsu China Automatic Fire Smoke Damper Roll Forming Machine

Technical Parameters:

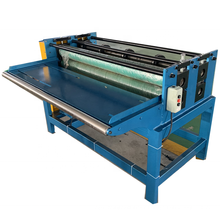

Equipment technique requirement: Equipment floor space: 23×3.0×2.5(L×W×H)meter. Equipment feeding material the orientation: The left side enter and right leave. Voltage: 380V,50Hz,3phase. Hydraulic oil : NO: .46# Gear oil: 18# Hypoid dear oil Equipment main technical parameters: Raw material width: around 196 mm Material thickness: G.I=0.7~1.2mm Material: Galvanized and stainless sheet Production speed: around 6M/min Production length: ≥3000mm Equipment total installed capacity: Around 20KW. Roll forming production scope This rollforming machine can be make the thickness from 0.8mm to 1.2mm Parameters of main equipment: 1 - De-coiler Material width:≤250 mm, Material thickness≤2.0mm; Inner diameter:480-520 mm; Outer diamete:φ1200mm; Max. Load capacity:≤2T 2 - Leveling system Use 9 roller leveling, Power 2.2 kW, Speed: 10M/min 3 - Servo feeding system BNC-30Technical parameters: BNC-300 The feed shaft diameter:φ60mm Measuring diameter of shaft:φ60mm Maximum feed plate of width:≤300mm Maximum feed plate of thickness:≤2.5mm Maximum feed speed:≤40m/min Feeding and blanking step length tolerance:±0.20mm Feed products overall length tolerance:±0.25mm Servo motor power/brand:1.3KW/Japan Yaskawa TransmissionSynchronous wheel / gear Length measuring encoder: ROUNDSS 2500P 4- Notching, punching hole and cutting Structure: hydraulic punching structure,the welded steel frame, has good inflexibility First notching dies: 2 sets First punching die:1 set After forming notching dies:2 sets After forming cutting die:1set 5 - Main rollforming machine Forming steps:14 group Forming framework: use the wall type side plategear drive Side wall thickness:25mm Max material width:≤196mm Min material thickness:0.7mm The roll shaft diameter:φ48 mm Roller material:Cr12MoV,the quenching hardness,HRC58-62° Use of double bearing design, bearing type 6208 The main drive motor uses 5.5kw frequency conversion motor.

6 - Cutting system a.ModalityHydraulic cutting b.Design featureafter cutting system design in the Forming Machine, the cutting Length can be set. 7 - Run-out table Framework: platform typewithout power 8 - Electrical control system 1-The whole line adopts PLC control, LCD touch screen display and man-machine interface software. (Interaction between workers and PLC.) The operator can do the following The setting program (PLC) Monitoring the control process, Modify the control parameters, The length of the workpiece digital setting, The length of the workpiece adjusting. Running state real-time monitoring equipment and fault indication. 2- Mode of operation: manual / auto two. With manual, automatic switching function: in the manual mode, can be stand-alone operation, convenient repair; in the automatic mode, all production and operation, the start up sequence; along with the emergency stop button, easy to handle emergencies, to ensure the safety of equipment and personnel.

Contact us if you need more details on Fire Damper Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Automatic Door Frame Roll Form Machine、Auto Msfd Frame Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Technical Parameters:

Equipment technique requirement: Equipment floor space: 23×3.0×2.5(L×W×H)meter. Equipment feeding material the orientation: The left side enter and right leave. Voltage: 380V,50Hz,3phase. Hydraulic oil : NO: .46# Gear oil: 18# Hypoid dear oil Equipment main technical parameters: Raw material width: around 196 mm Material thickness: G.I=0.7~1.2mm Material: Galvanized and stainless sheet Production speed: around 6M/min Production length: ≥3000mm Equipment total installed capacity: Around 20KW. Roll forming production scope This rollforming machine can be make the thickness from 0.8mm to 1.2mm Parameters of main equipment: 1 - De-coiler Material width:≤250 mm, Material thickness≤2.0mm; Inner diameter:480-520 mm; Outer diamete:φ1200mm; Max. Load capacity:≤2T 2 - Leveling system Use 9 roller leveling, Power 2.2 kW, Speed: 10M/min 3 - Servo feeding system BNC-30Technical parameters: BNC-300 The feed shaft diameter:φ60mm Measuring diameter of shaft:φ60mm Maximum feed plate of width:≤300mm Maximum feed plate of thickness:≤2.5mm Maximum feed speed:≤40m/min Feeding and blanking step length tolerance:±0.20mm Feed products overall length tolerance:±0.25mm Servo motor power/brand:1.3KW/Japan Yaskawa TransmissionSynchronous wheel / gear Length measuring encoder: ROUNDSS 2500P 4- Notching, punching hole and cutting Structure: hydraulic punching structure,the welded steel frame, has good inflexibility First notching dies: 2 sets First punching die:1 set After forming notching dies:2 sets After forming cutting die:1set 5 - Main rollforming machine Forming steps:14 group Forming framework: use the wall type side plategear drive Side wall thickness:25mm Max material width:≤196mm Min material thickness:0.7mm The roll shaft diameter:φ48 mm Roller material:Cr12MoV,the quenching hardness,HRC58-62° Use of double bearing design, bearing type 6208 The main drive motor uses 5.5kw frequency conversion motor.

6 - Cutting system a.ModalityHydraulic cutting b.Design featureafter cutting system design in the Forming Machine, the cutting Length can be set. 7 - Run-out table Framework: platform typewithout power 8 - Electrical control system 1-The whole line adopts PLC control, LCD touch screen display and man-machine interface software. (Interaction between workers and PLC.) The operator can do the following The setting program (PLC) Monitoring the control process, Modify the control parameters, The length of the workpiece digital setting, The length of the workpiece adjusting. Running state real-time monitoring equipment and fault indication. 2- Mode of operation: manual / auto two. With manual, automatic switching function: in the manual mode, can be stand-alone operation, convenient repair; in the automatic mode, all production and operation, the start up sequence; along with the emergency stop button, easy to handle emergencies, to ensure the safety of equipment and personnel.

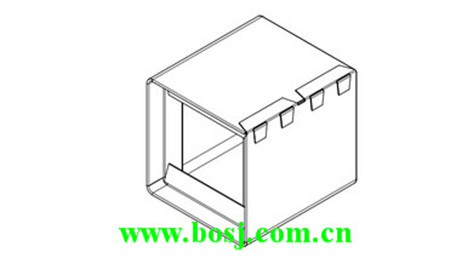

| NO. | Project | Unit | parameters | Remark | |

| 1 | Material | type | Mild steel Galvanized sheet | ||

| Strength of material sheet | Map | ≥350 | |||

| Thickness of material sheet | mm | 0.8~1.5 | |||

| 2 | Size of production | mm | Reference the picture | ||

| 3 | Production speed | m/min | 6~8 | ||

| 4 | Material of roller | GCr quenching treatment | |||

| 5 | Drive type | Gear box | |||

| 6 | Power | kw | About 34 | ||

| 7 | Electric control system | PLC variable frequency control | |||

| 8 | Dimensions(Length*width*height) | m | 28X4X3.9 | ||

Contact us if you need more details on Fire Damper Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Automatic Door Frame Roll Form Machine、Auto Msfd Frame Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Vane Damper Roll Forming Machine

Other Products

Hot Products

Support Steel Post for Grape Garden Roll Forming Machine Supplier AustraliaInternal Combustion Engine Turbocharger Compressor Wheel TurbobilletCustomized Pre-Galvanized Scaffold Foot Planks Scaffolding SystemGalvanized Solar Stand Roll Forming Machine Manufacturer for Saudi AabiaAuto China CNC Plasma Cutting Machine for RussiaAuto Car Collision Beam Roll Forming Machine Maunfacturer DubaiAuto China Cable Tank Ladder Roll Forming MachineSupermarket Steel Shelf Storage Deck Panel Roll Forming MachineMsfd VCD HVAC Fire Damper Shutter Frame Blade Louver Roll Forming MachineMarine Steel Scaffolding Planks Board Walkboard Roll Forming Production MachineAuto Steel Silo Corrugated Sheet Roll Forming Machine-BosjAuto Swisss Electric Cabinet Purlin Roll Forming Machine (BOSJ)Two Thire Waves W-Beam Highway Guardrail Roll Forming (BOSJ)C/Z/U/Omiga Purlin Exchange Roll Forming (BOSJ03)Steel Scaffolding Planks Board Roll Forming Line Manufacturer MalaysiaAutomatic Galvanized Steel Cable Tray Cold Roll Forming Machine (BOSJ)