Drywall stud track roll forming machine

Product Description

Drywall stud track Roll Forming Machine

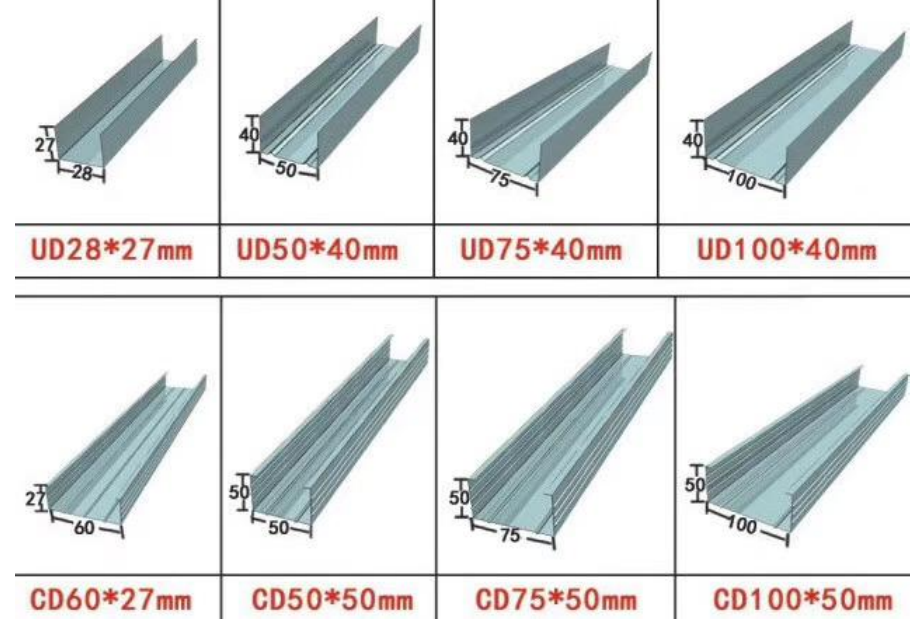

Metal Stud and Track have become a competitive and widely used product in building industry giving a fireproof and easily erected system for partitioning and various other uses. The component parts of the system are ideal rollform applications. Metal Track and Studs profiles are used for Drywall partition and ceiling suspension in the commercial and residential application.

The machine of Stud and track machine CU 50-150 profile making machine allows you to make the sizes from 50 to 150 width range adjustment by the PLC. The punching is also adjustable by PLC. The machine working speed can reach 45 meter per minutes.

Here are some profile drawings for your reference:

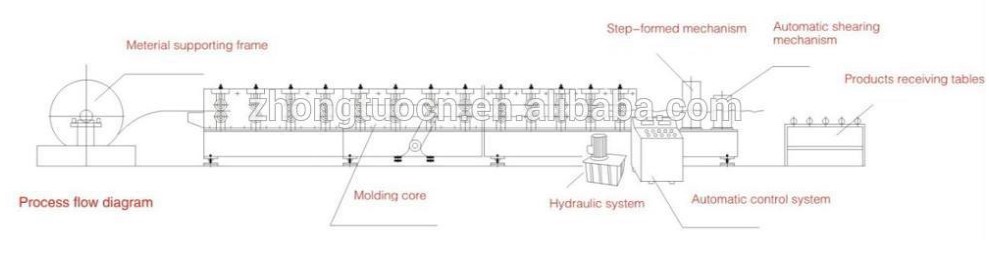

Structure of Drywall Stud Track Roll Forming Machine

This roll forming machine consists of 3 tons manually uncoiler, chain driven transmission, forming rollers, mainframe(including guiding platform), cutting, hydraulic system and stacker.

The whole production process including punching and cutting is controlled by PLC, rollers manually adjustment if different dimensions of manufacturing are needed.

Work flow:Uncoiling→ Feeding material into machine →Roll forming → Auto shearing →Products receiving table

| 1 | Machine name | Drywall stud track roll forming machine |

| 2 | Dimension | 8500*1500*1500mm |

| 3 | Weight | 4.5T |

| 4 | Total power | 16.5KW |

| 6 | Voltage | 380V/50HZ/3PH |

| 7 | Material | PPGL,PPGIGI,GL |

| 8 | Forming speed | 0-8m/min |

| 9 | Material thickness | 0.8-1.2mm |

| 10 | Tolerance | ±1mm |

Main pictures of Drywall stud track roll forming machine:

Manual decoiler of Drywall stud track roll forming machine:

Loading capacity:3T

coil width:300 mm

PLC control system of Drywall stud track roll forming machine:

Operating language:English and Chinese(customized)

PLC brand:Delta(Taiwan famous brand)

Eletrical components:Schneider

Hydraulic oil station of Drywall stud track roll forming machine:

Hydraulic power:5.5KW

Hydraulic oil:46# hydraulic oil

With cooling fan

The advantages of Drywall stud track roll forming machine with size-quick- change type are as follows:

1. Produce different products size without changing rollers or spacers.

2. Easy operation, low maintenance cost

3. Infinite sizing (any size within machine range),help to save material

Usage of drywall stud and track:

1.How to get a quotation of Drywall stud track roll forming machine?

Send me the profile drawing and thickness ,this is most important.

Other spicific requirements is welcomed,such as the forming speed,working voltage you want.

2. Terms of payment:

30% T/T, Balance to be paid before shipping after inspection.Also we accept the payment L/C, O/A , D/P.

3. How long it will take for producing Drywall stud track roll forming machine?

Normally speaking,producing Drywall stud track roll forming machine will takes about 45 working days.

4. What is your after-sale service?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send new to replace for free,but you need to pay the express cost yourself,and we supply the technical support for the whole life.

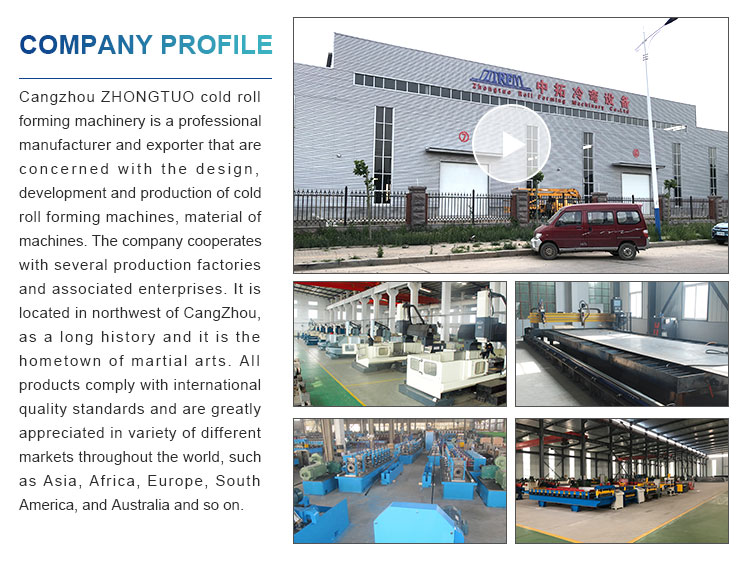

5. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines.

6. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

Product Categories : strut track roll forming machine