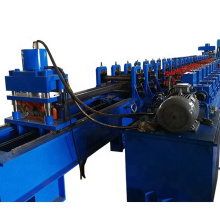

Light-Duty Warehouse Metal Rack Roll Forming Production Machine Iran

Basic Info

Model No.: BOSJ-S

Product Description

Model NO.: BOSJ-S

Forging Forming Method: Tire Mold Forging

Feature: Automation

Warranty: 12 Months

Advantage: Easy to Maintenance

Control System: PLC

Making Machine: Multifunctional

Trademark: BOSJ

HS Code: 8455212000

Type: Rolling Machine

Power Source: Hydraulic Pressure

Certification: SGS, ISO9001

Customized: Customized

Condition: New

After-Sales Service Provided: Engineers Available to Service Machinery Overseas

Material of Roller: Gcr 15

Origin: Wuxi

Supermarket Steel Shelf Storage Deck Panel Roll Forming

Equipment structure

The equipment is consisted with auto-de-coiler, guide frame, lever/feeding section, continuous bottom hole punching section, forming section, positioning and cutting section, collection table and electrical control system etc.

Shelf Forming Machine is Jiangyin Bosj Technology Co.,Ltd. According to market demand by the collection year production cold rolling equipment experience independently designs a series or products.

Product: Shelf column, Shelf crossbeam, Shelf stay rod, Shelf plywood etc.

Equipment capacity:

1, Equipment production capacity: width≤400mm, thickness of steel material: 1-2.5mm

2, Production speed: 8-15m/min

3, Total power: about 21.5kw

Structure of Heavy Duty Pallet Racking.

Beams

Horizontal bracing

Diagonal bracing

Uprights

Screw, safe pins

Protector

Trays ,pallets ,or steel mesh plates

Determinant of Heavy Duty Pallet Racking design

1. The weight of your goods (trays, steel containers / boxes are included)

2. The dimension of your goods together with pallets ( Length Width Height )

3. The maximum height of your forklift and the available height of your warehouse

4. The dimension of your forklift

5. The fork direction

6. The dimension of your warehouse

7. The path of the transportation

Advantages of Heavy Duty Pallet Racking .

1.It is suitable to be used in factories, manufactures and warehouse

2.Size(L*W*H): 1200/1500/2000*450/600/1000*1800/2000/2500mm

3.Perfect for storing categorized products in a neat and tidy way

4.heavy-duty shelf set for warehouse shelving

5.Strong structure

6.Easy installation

7.Customization is acceptable

Main Machine Parameter

| NO. | Name | unit | parameter | remark | |

| 1 | materials | type | Mild steel,galvanized sheet | ||

| Plate strength | Map | ≥350 | |||

| Plate thickness | mm | 1.0~1.6 | |||

| 2 | specification | mm | See the pictures | ||

| 3 | speed | m/min | 18 | ||

| 4 | Material of the roller | GCr15,Hardening treatment | |||

| 5 | drive type | Gear box | |||

| 6 | power | kw | About 35.5 | ||

| 7 | Electrical control system | PCL frequency control | |||

| 8 | Size(lengthXwidthXheight) | m | 20X4X3.9 | ||

| Main Accessories | ||

| 1 | Decoiler | 1 set |

| 2 | Main Forming Machine | 1 set |

| 3 | Correction System | 1 set |

| 4 | Hydraulic Station | 1 set |

| 5 | Auto-Cutting system | 1 set |

| 6 | PLC Control System | 1 set |

| 7 | Run Out Table | 1 set |

| Technical Datas Roll Forming Machine | ||

| 1 | Material width | As your regards |

| 2 | The effective width | As your regards |

| 3 | The thickness of Coil | 1.0-3.0mm or more |

| 4 | Application | wall sheet and roof sheet |

| 5 | The overall dimensions | 6800mmX1500mmX1300mm |

| 6 | Total weight | 5 Tons |

| 7 | Main Power | 5.5 KW |

| 8 | Uncoiler | Manual Uncoiler |

| 9 | Inner diameter | 508--610mm |

| 10 | Outer diameter | 1200mm |

| 11 | Loading weight | 3T |

| 12 | Forming speed | 5-10m/min |

| 13 | Forming steps | 12 stations or more |

| 14 | Bracket | welded with 36 # I-steel |

| 15 | Material of Shafts | 45# steel with rough finished and then refined finished |

| 16 | Diameter of the Roll | 76mm |

| 17 | Material of Rolls | high quality 45#steel coated with hard chromium 0.05 mm |

| 18 | Processing Technology | rough processing ---refined processing--Hard Chromium Plating. |

| 19 | Material of Rack | complete welded structure of A3 steel plate 16mm thickness |

| 20 | Transmission | Transmitted by the chain-bracket/ Gearbox T180 |

| 21 | Material of Chain | 45#steel with heat treatment of HRC45-50° |

| 22 | Holders under chain for lubricant | By the machine |

| 23 | Material of cutting blade | Cr12 with quenched treatment 60-62 |

| 24 | Cutting system | Hydraulic cutting |

| 25 | Voltage | 380V/50HZ/3phase |

Delivery Of Machine

Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roll Forming、Metal Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Storage Rack Beam Roll Forming Machine

Premium Related Products

Other Products

Hot Products

Support Steel Post for Grape Garden Roll Forming Machine Supplier AustraliaInternal Combustion Engine Turbocharger Compressor Wheel TurbobilletCustomized Pre-Galvanized Scaffold Foot Planks Scaffolding SystemGalvanized Solar Stand Roll Forming Machine Manufacturer for Saudi AabiaAuto China CNC Plasma Cutting Machine for RussiaAuto Car Collision Beam Roll Forming Machine Maunfacturer DubaiAuto China Cable Tank Ladder Roll Forming MachineSupermarket Steel Shelf Storage Deck Panel Roll Forming MachineMsfd VCD HVAC Fire Damper Shutter Frame Blade Louver Roll Forming MachineMarine Steel Scaffolding Planks Board Walkboard Roll Forming Production MachineAuto Steel Silo Corrugated Sheet Roll Forming Machine-BosjAuto Swisss Electric Cabinet Purlin Roll Forming Machine (BOSJ)Two Thire Waves W-Beam Highway Guardrail Roll Forming (BOSJ)C/Z/U/Omiga Purlin Exchange Roll Forming (BOSJ03)Steel Scaffolding Planks Board Roll Forming Line Manufacturer MalaysiaAutomatic Galvanized Steel Cable Tray Cold Roll Forming Machine (BOSJ)