shutter door U guide tracks roll forming machine

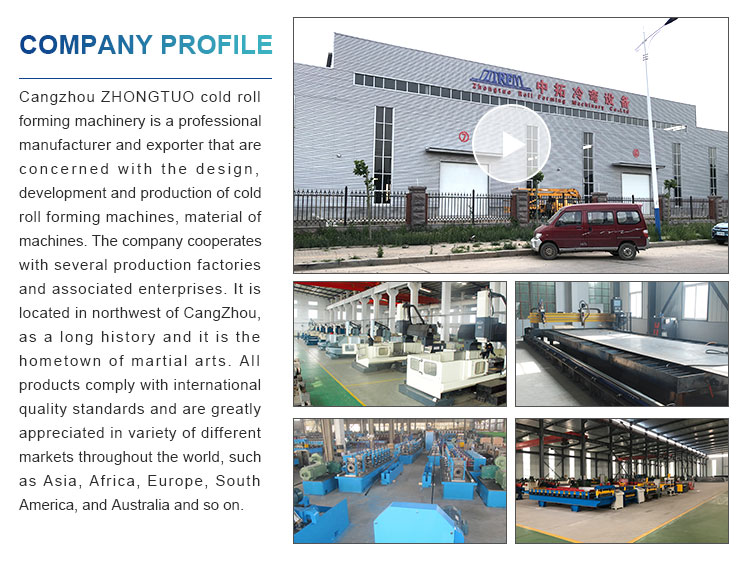

Product Description

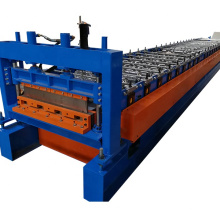

shutter door U guide tracks Roll Forming Machine

![]()

Usage:

This machine is for produce the shutter door U guide tracks,with full automatic.

just need to control the PLC system,put in the data of order and automatic produce.(need 1-2 person for operation)

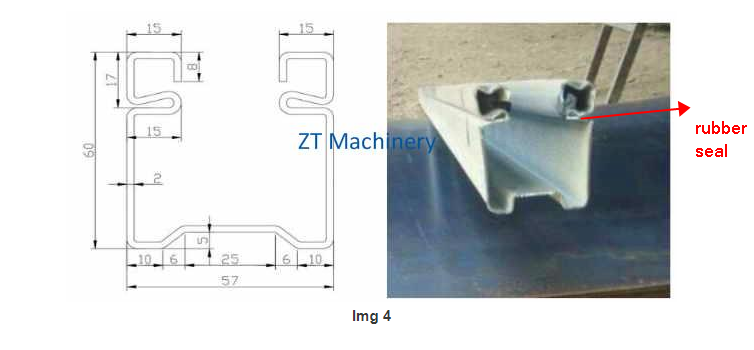

The finished products:

Here are some pictures of finished products for your reference.(As the draw profiles are customized,You can also let us make the machine for produce the finished products you want)

(You can choose whether need the rubber filling device)

![]()

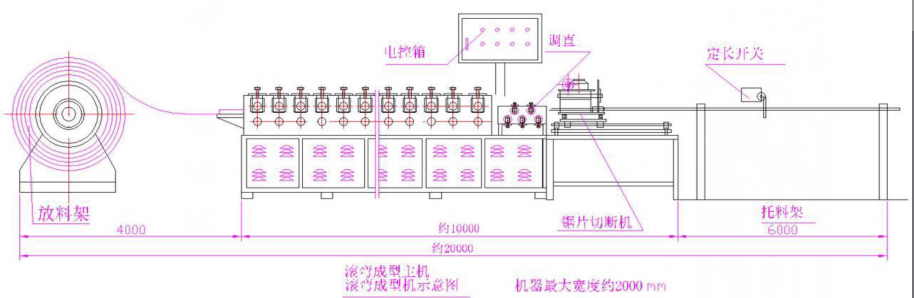

Working process:

Decoiler --leveling-- Rolling Forming-- Shearing system with punchin-- runout table

Parameters of each part:

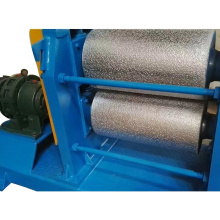

| Manual Decoiler

| Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system a.Coil inner diameter: 450-550mm b.Coil max width: 300mmc. Max carrying capacity: 5000kg |

| Leveling system | This part will level coil to make sure it is neat clean and straight. |

| Main roll Forming Machine

| a. Number of forming steps: 18 stations B. Shaft material: 45# steel with quenched treatment, precision machined, The diameter: 90mm c. Roller material: Cr12 Mov with quenched treatment d.Transport: by gearbox e. Forming speed: 25m/min g. Voltage: 380v, 50Hz,3 phase or customize h. Structure: independent stand |

| Shearing system | The material of blade: Cr12Mov, Hardening HRC 58-62℃ Length Tolerance:3m±1.0mm |

| Hydraulic station | Hydraulic motor Power: 3kw Hydraulic oil: 46# Hydraulic pressure: 12 Mpa Brand: Chinese famous brand. Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes. And two sets of electromagnetism valves. |

| PLC Control system | Feature: Adopted PLC, transducer, touch panel from Mitsubishi Japan to ensure high speed with stability, precision and lifetime. Other electric element is Schneider Equipped with movable switch, air break, radiator, transformer & electric leakage protector, that element can make sure easy operation convenience and safety. Brand: Delta Taiwan brand or Semen Germany brand or Panasonic, Japan brand. |

| Runout table | It adopts welded steel and supported roller to transmit the products. |

| (If you need fill rubbers on the roll forming line can also tell us) Spare parts: 1. Easy damaged parts: conk 2 pcs, fuse-link 4 pcs; 2. Rubber mat 1 pcs; 3. Bolt spanner 1 pcs

| |

![]()

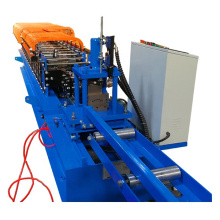

(the rubber filling device(If you need fill rubber will add this device on the roll forming part)

![]()

No.1 shutter door roll forming machine(Click picture to buy)

No.2 shutter door beam roll forming machine(Click to buy)

No.3 shutter door tube of the head(Click to buy)

![]()

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 6 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

6. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines.

7. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing How to make machines much more automatic, accurate and high quality. We can make sure thatour machine could use more than 20 years without any problem. We can provide 2 years free qualityassurance.

8. How long the machine could be made?

Normally speaking, welded pipe making machine could be made without 45 working days. If you need machines in a hurry, we can make it for you less than a month.

Product Categories : door making machine > rolling shutter forming machine

Premium Related Products