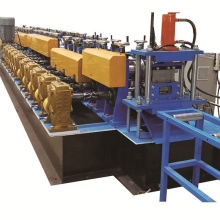

UPRIGHT MACHINE

Product Description

Product Description

Specification

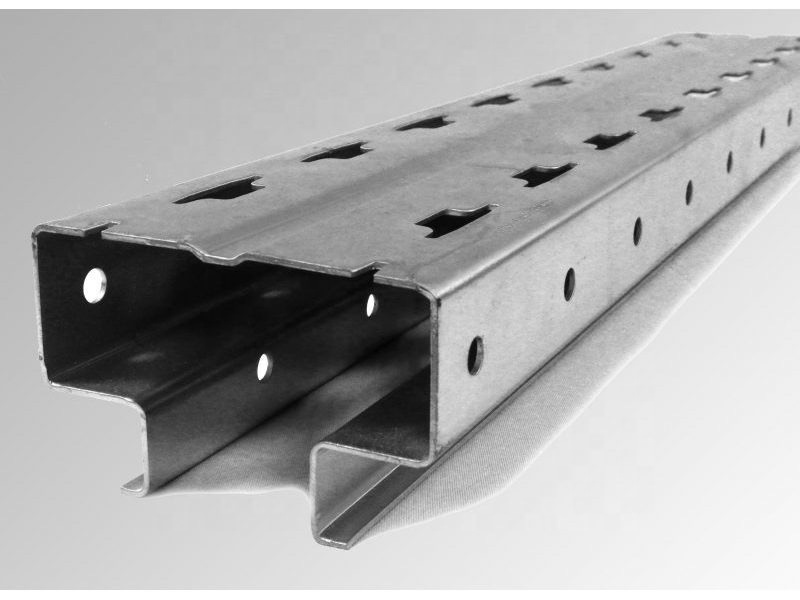

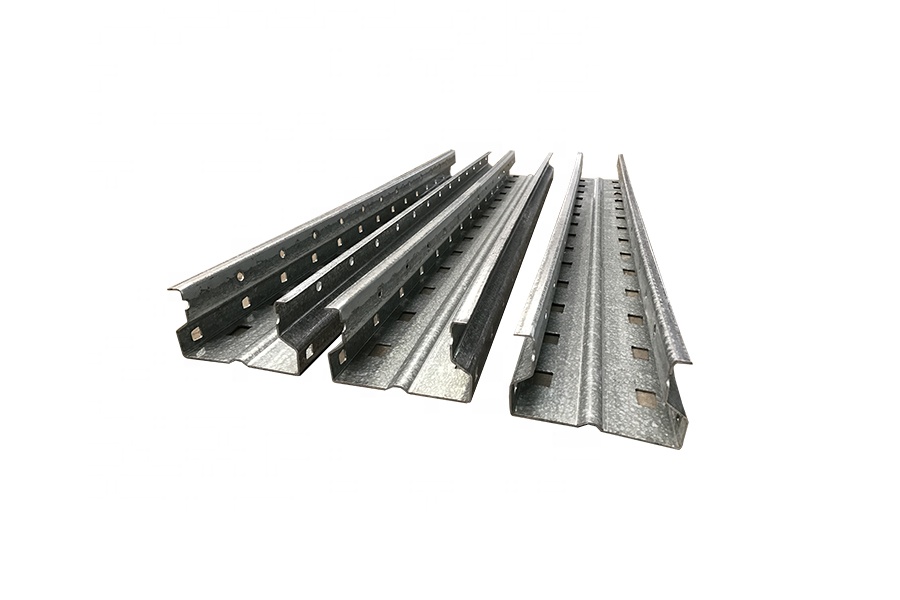

Material: 1.5 mm Minimum Thickness, 3.0mm Maximum Thickness The 2.5mm or 3.0mm thickness raw material for inspection, in common use Effective width:90/100/110/120/130/140/150 Feeding width: ??mm;-Shall reconfirm after test run. Cold rolled steel coil, Galvanized Coil, Tension: 350~450Mpa | 100T Professional power press machine Press: 100Ton, Main motor: 7.5KW Step length: Shall be double checked! Total One sets for punching die, material: Cr12MoV, Heat Treatment(HRC60~61) Improved design of the tooling and the structure, please refer to below pictures |

Servo Feeder Operating with Computerize Numerical Control by PLC program to automatic feed the strip material to the press. Main Technical Data: Work Roll: Quantity of Rolls – 2 Size of Rolls – Ø75 MM Material – 40Cr Hardness – 52 to 60HRC Servo motor Power: 1.5KW | The feeding section with guide; CHAINS/SPROCKET DRIVEN, Total 40 stages to form, HEAVY FRAME STAND TYPE Rollers manufactured from Cr12 steel, CNC lathes, Fine polished, Heat Treatment (HRC58~62) Shaft Diameter=Φ95mm, Precision Machined, CNC LATHE, Hardening and Tempering. Motor of changing profile size: 4*1.1KW (For flange change), 1*1.5KW (For Web change) Main motor for roll forming: 18KWx4, frequency speed control |

PLC Control cabinet one unit; Control the quantity, punching hole & cutting length automatically. Combined with: PLC(SIEMENS), Touch Screen(SIEMENS),inverter(SCHNEIDER), Encoder(Omron), etc Cut-to-length tolerance:≤±2 mm Control voltage :24V | Non-Stop-to-Cut, post Cut, no blanking cut Cutting tool material: Cr12, Heat treatment Total ONE sets of cutting tools hydraulic group motor=11KW The cutting carriage is movable on smooth rails The forming speed would be decreased when holding the sheet and then cut-off Mechanical switch to assistant to fix the sheet |

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

FAQ

INDUSTRY UPRIGHT PRODUCTION LINE IT CAN MAKE DIFFERENT SIZE BASIS ON RACKING SYSTEM REQUEST. IT SAVE MORE LABOR COST FOR TRADITIONAL PROCESS.

Product Categories : RACKING SYSTEM MACHINES

Premium Related Products

Other Products

Hot Products

Support Steel Post for Grape Garden Roll Forming Machine Supplier AustraliaInternal Combustion Engine Turbocharger Compressor Wheel TurbobilletCustomized Pre-Galvanized Scaffold Foot Planks Scaffolding SystemGalvanized Solar Stand Roll Forming Machine Manufacturer for Saudi AabiaAuto China CNC Plasma Cutting Machine for RussiaAuto Car Collision Beam Roll Forming Machine Maunfacturer DubaiAuto China Cable Tank Ladder Roll Forming MachineSupermarket Steel Shelf Storage Deck Panel Roll Forming MachineMsfd VCD HVAC Fire Damper Shutter Frame Blade Louver Roll Forming MachineMarine Steel Scaffolding Planks Board Walkboard Roll Forming Production MachineAuto Steel Silo Corrugated Sheet Roll Forming Machine-BosjAuto Swisss Electric Cabinet Purlin Roll Forming Machine (BOSJ)Two Thire Waves W-Beam Highway Guardrail Roll Forming (BOSJ)C/Z/U/Omiga Purlin Exchange Roll Forming (BOSJ03)Steel Scaffolding Planks Board Roll Forming Line Manufacturer MalaysiaAutomatic Galvanized Steel Cable Tray Cold Roll Forming Machine (BOSJ)