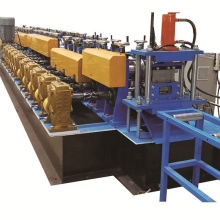

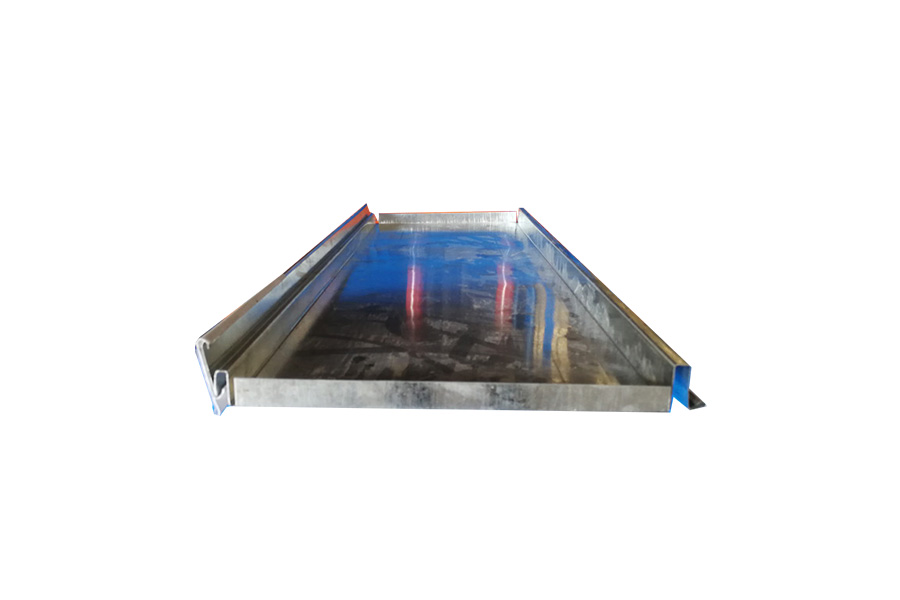

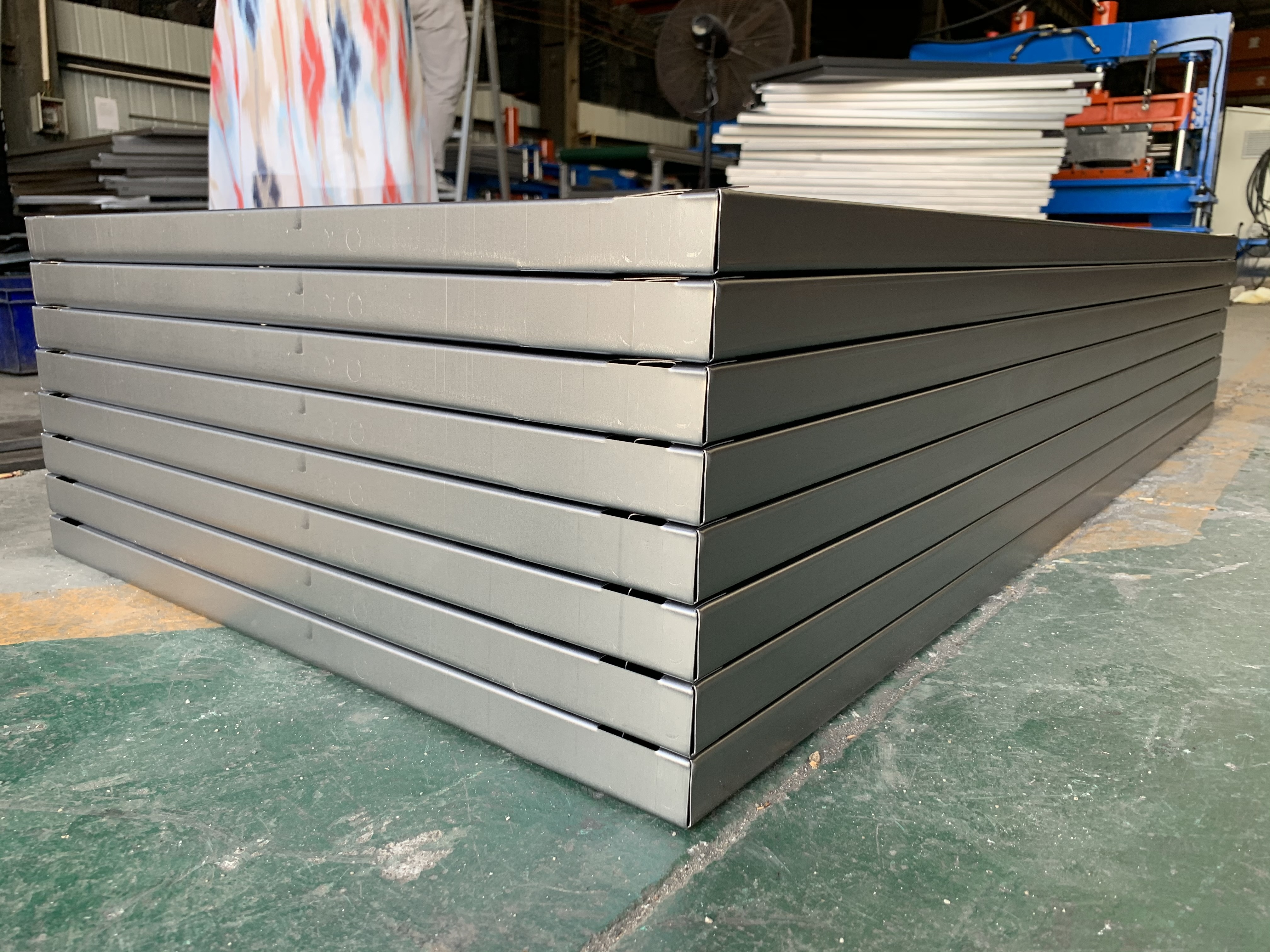

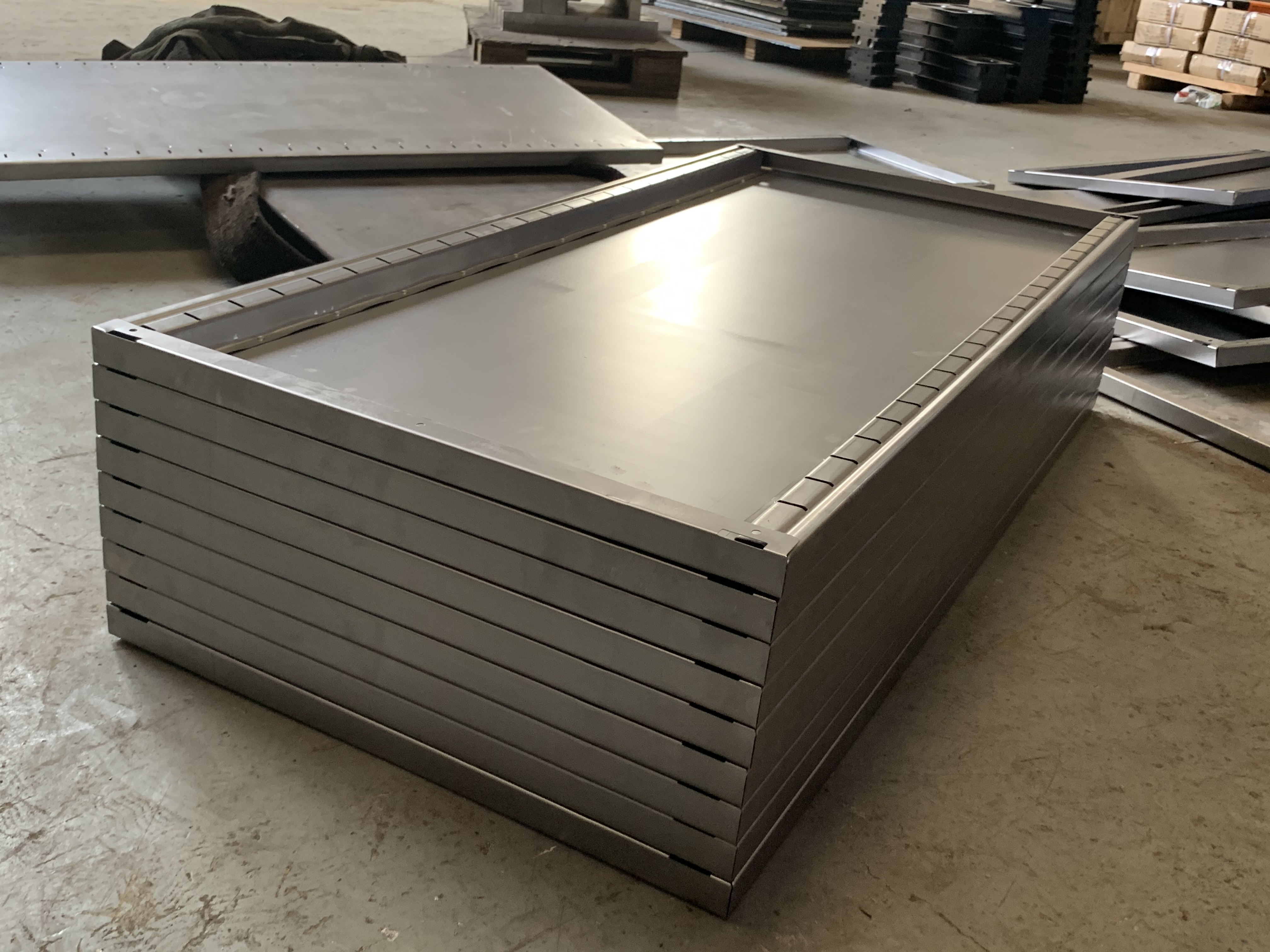

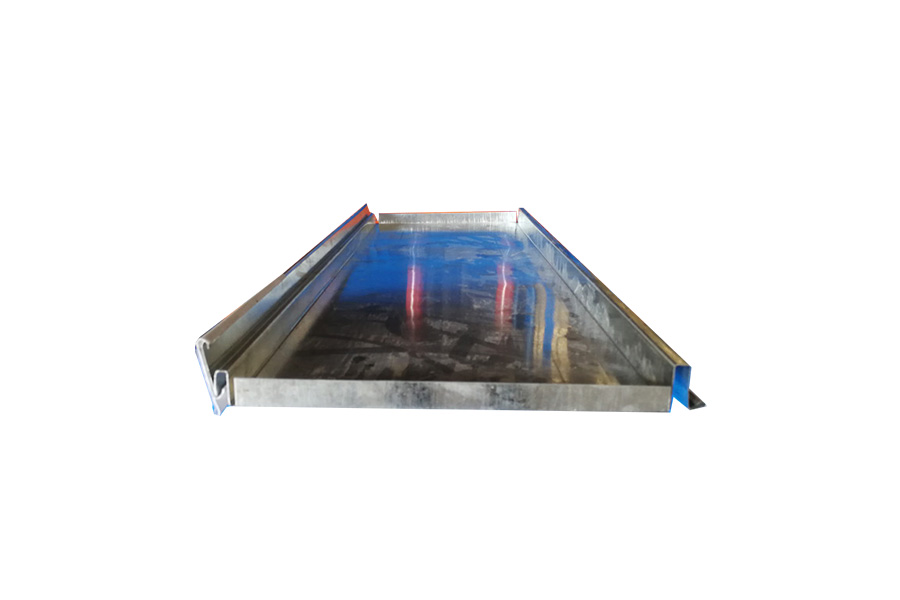

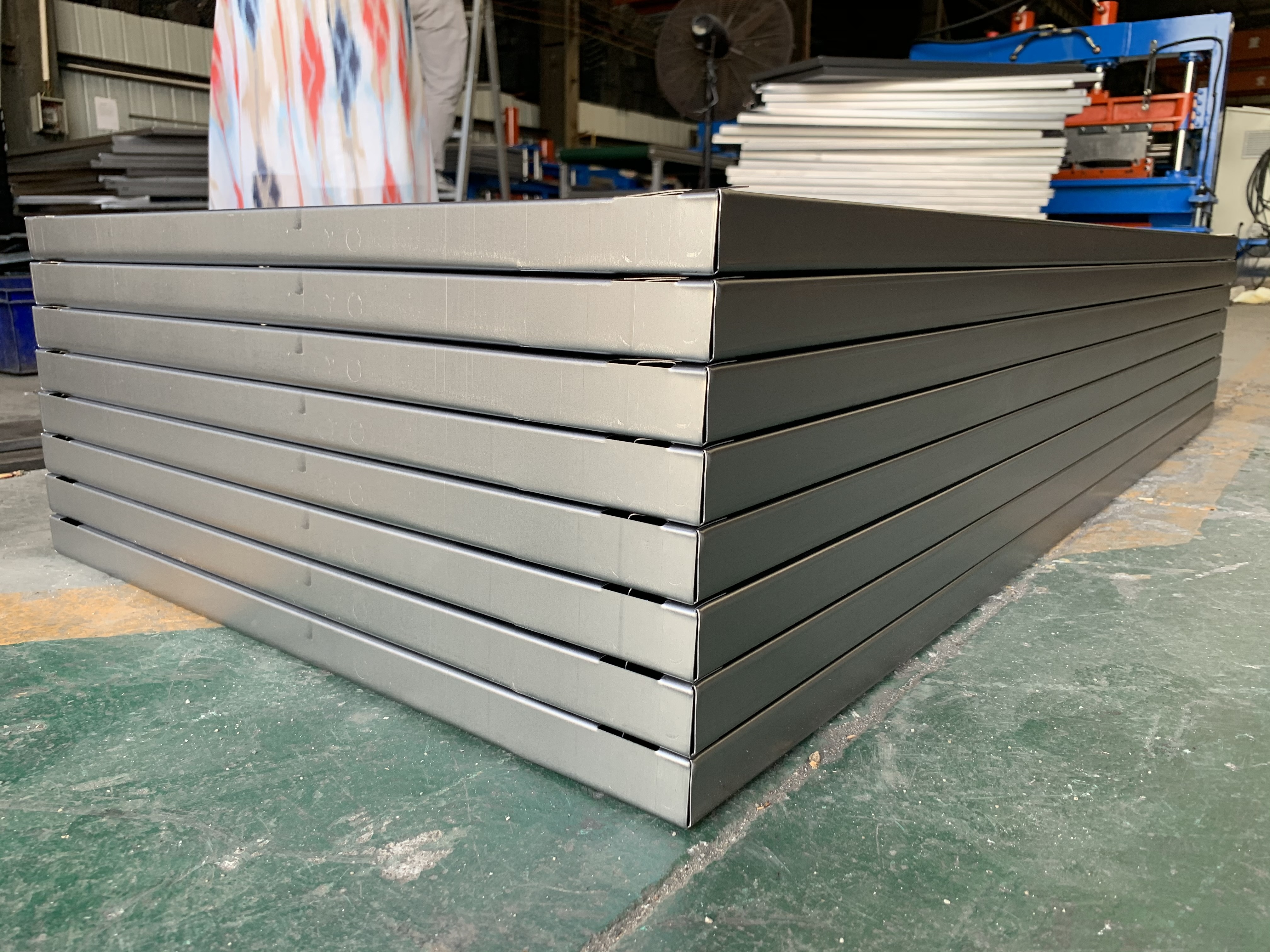

Fully Automatic Supermarket Shelf Panel Shelves Storage Racks Roll Forming Machine Production Line

Product Description

Product Description

Specification

Specification

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. Company Profile

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. Company Profile

Company InformationRELIANCE MACHINE (formally named as Xiamen Reliance M&N Machinery Industries Co., Ltd) was established in 2016, which covers an area of MORE THAN 10,000 SQUARE METERS. With 20 YEARS PROFESSIONAL EXPERIENCE, Meanwhile, we are the main drafter standard of China Non-standard roll former manufacturer and exporter of high quality roll forming machines in China. We are an ISO9001 approved company, and have European CE certification

Company InformationRELIANCE MACHINE (formally named as Xiamen Reliance M&N Machinery Industries Co., Ltd) was established in 2016, which covers an area of MORE THAN 10,000 SQUARE METERS. With 20 YEARS PROFESSIONAL EXPERIENCE, Meanwhile, we are the main drafter standard of China Non-standard roll former manufacturer and exporter of high quality roll forming machines in China. We are an ISO9001 approved company, and have European CE certification

We manufacture wide range products of metal sheet roll forming machines as follows: 1) for Metal Building Industry/PEB (Pre-Engineering Building): HAYES style quick change CZ purlin machine(including automatic and quick-change type C purlin machine and Z purlin machine), light gauge steel framing machine(LGSF, Howick and SCOTTSDALE style), roof panel Forming Machine, corrugated panel Roll Forming Machine, curving machine, glazed Tile Roll Forming Machine, floor decking machine, ridge cap roll forming machine, cladding facade system forming machine, cut-to-length slitting line etc., as well as some hydraulic shearing machine, hydraulic folding machine for gutter and flashing, etc.

Exhibition

Packing & Delivery

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. FAQ 1. Could I have prices of your products? Welcome. Please feel free to send us an email here. You will get our reply in 24 hours 2. Can we print our logo/website/company name on products? Yes 3. What's the lead time for regular order? 7-15 days for order quantity lower than 10pc 4. Can I get a discount? Yes, please contact us to get the best price. 5. Do you inspect the finished products? Yes, each step of production and finished products will be came out inspection by QC department before shipping. Contact us if you need more details on Storage Racks Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Shelf Panel Roll Forming Machine、Fully Automatic Shelf Panel Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. FAQ 1. Could I have prices of your products? Welcome. Please feel free to send us an email here. You will get our reply in 24 hours 2. Can we print our logo/website/company name on products? Yes 3. What's the lead time for regular order? 7-15 days for order quantity lower than 10pc 4. Can I get a discount? Yes, please contact us to get the best price. 5. Do you inspect the finished products? Yes, each step of production and finished products will be came out inspection by QC department before shipping. Contact us if you need more details on Storage Racks Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Shelf Panel Roll Forming Machine、Fully Automatic Shelf Panel Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Specification

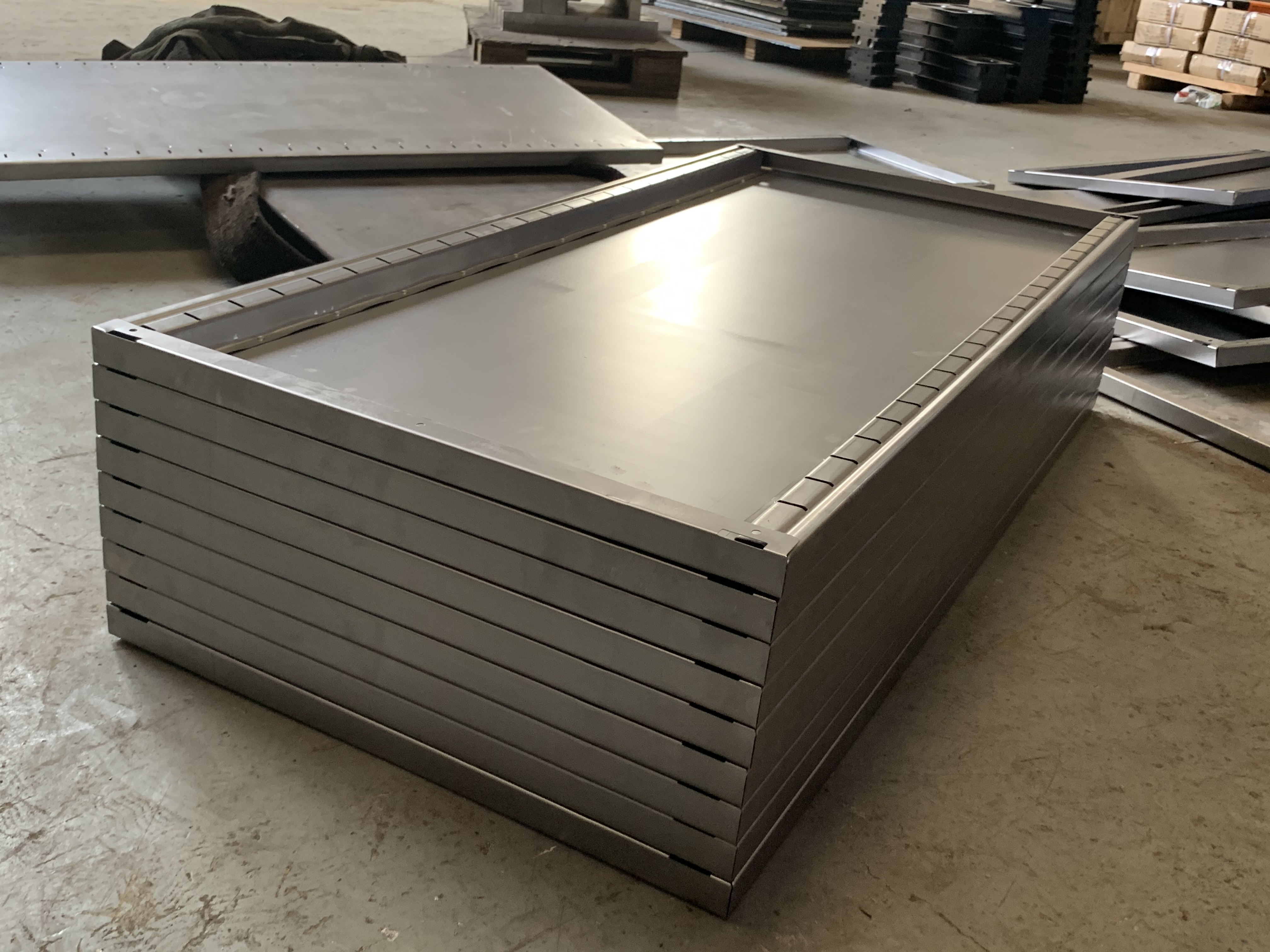

Specification The 0.7mm thickness raw material for inspection, in common use Effective width: 300MM/400MM/500MM/600MM Feeding width: Approx. 815mm for 600 shelf;Length: 1250~1500mm Cold rolled steel coil, Galvanized Coil, Tension: Q235 | The In-feed Section of the machine allows for variations in sheet width Pre-Level Device with 3 over 2 shafts to remove the Coil-set All the shafts will be highly precision machining with hard chrome Servo Feeder motor=3KW |

Totally two sets of hydraulic cylinders for notching&holes Notching & punching die: Cr12, Heat Treatment, HRC58~62(More spare parts for pin tools) Stop to notch holes/punching at one time Variable programmable longitudinal positions | H Beam basis, All the wall plates with NC machining Chains/Sprockets driving, 24-step to form, Wall plate connecting design Rollers manufactured from 45# steel, CNC lathes, Fine polished, Hard Chrome, (NOTE: Partial idle rollers with heat treatment purpose) Shaft Diameter=Φ75mm, Precision Machined, CNC LATHE, Hardening and Tempering. |

Main motor for roll forming: 11KW, Frequency speed control Motor for size changing: 1.5KW | Stop to cut, Post cut, Slug breaker Share with pre-punch/notch hydraulic power Cutting tool material : Cr12, Heat treatment;HRC58~62 Mould steel with quenched treatment |

Powered conveyor table | Hydraulic bending device |

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. Company Profile

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. Company Profile

Company InformationRELIANCE MACHINE (formally named as Xiamen Reliance M&N Machinery Industries Co., Ltd) was established in 2016, which covers an area of MORE THAN 10,000 SQUARE METERS. With 20 YEARS PROFESSIONAL EXPERIENCE, Meanwhile, we are the main drafter standard of China Non-standard roll former manufacturer and exporter of high quality roll forming machines in China. We are an ISO9001 approved company, and have European CE certification

Company InformationRELIANCE MACHINE (formally named as Xiamen Reliance M&N Machinery Industries Co., Ltd) was established in 2016, which covers an area of MORE THAN 10,000 SQUARE METERS. With 20 YEARS PROFESSIONAL EXPERIENCE, Meanwhile, we are the main drafter standard of China Non-standard roll former manufacturer and exporter of high quality roll forming machines in China. We are an ISO9001 approved company, and have European CE certification We manufacture wide range products of metal sheet roll forming machines as follows: 1) for Metal Building Industry/PEB (Pre-Engineering Building): HAYES style quick change CZ purlin machine(including automatic and quick-change type C purlin machine and Z purlin machine), light gauge steel framing machine(LGSF, Howick and SCOTTSDALE style), roof panel Forming Machine, corrugated panel Roll Forming Machine, curving machine, glazed Tile Roll Forming Machine, floor decking machine, ridge cap roll forming machine, cladding facade system forming machine, cut-to-length slitting line etc., as well as some hydraulic shearing machine, hydraulic folding machine for gutter and flashing, etc.

Exhibition

Packing & Delivery

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. FAQ 1. Could I have prices of your products? Welcome. Please feel free to send us an email here. You will get our reply in 24 hours 2. Can we print our logo/website/company name on products? Yes 3. What's the lead time for regular order? 7-15 days for order quantity lower than 10pc 4. Can I get a discount? Yes, please contact us to get the best price. 5. Do you inspect the finished products? Yes, each step of production and finished products will be came out inspection by QC department before shipping. Contact us if you need more details on Storage Racks Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Shelf Panel Roll Forming Machine、Fully Automatic Shelf Panel Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. FAQ 1. Could I have prices of your products? Welcome. Please feel free to send us an email here. You will get our reply in 24 hours 2. Can we print our logo/website/company name on products? Yes 3. What's the lead time for regular order? 7-15 days for order quantity lower than 10pc 4. Can I get a discount? Yes, please contact us to get the best price. 5. Do you inspect the finished products? Yes, each step of production and finished products will be came out inspection by QC department before shipping. Contact us if you need more details on Storage Racks Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Shelf Panel Roll Forming Machine、Fully Automatic Shelf Panel Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : RACKING SYSTEM MACHINES

Premium Related Products

Other Products

Hot Products

Support Steel Post for Grape Garden Roll Forming Machine Supplier AustraliaInternal Combustion Engine Turbocharger Compressor Wheel TurbobilletCustomized Pre-Galvanized Scaffold Foot Planks Scaffolding SystemGalvanized Solar Stand Roll Forming Machine Manufacturer for Saudi AabiaAuto China CNC Plasma Cutting Machine for RussiaAuto Car Collision Beam Roll Forming Machine Maunfacturer DubaiAuto China Cable Tank Ladder Roll Forming MachineSupermarket Steel Shelf Storage Deck Panel Roll Forming MachineMsfd VCD HVAC Fire Damper Shutter Frame Blade Louver Roll Forming MachineMarine Steel Scaffolding Planks Board Walkboard Roll Forming Production MachineAuto Steel Silo Corrugated Sheet Roll Forming Machine-BosjAuto Swisss Electric Cabinet Purlin Roll Forming Machine (BOSJ)Two Thire Waves W-Beam Highway Guardrail Roll Forming (BOSJ)C/Z/U/Omiga Purlin Exchange Roll Forming (BOSJ03)Steel Scaffolding Planks Board Roll Forming Line Manufacturer MalaysiaAutomatic Galvanized Steel Cable Tray Cold Roll Forming Machine (BOSJ)