Fully Auto Forming Sheet Making Machine

Product Description

Fully Auto Forming Sheet Making Machine

our advantages

1.QUALITY. specialized in Roll Forming Machine field over 23 years.

2.WARRANTY. one year guarantee + technology support lifetime.

3.CAPABILITY. market leader. certificated with ISO9001, CE, SGS,

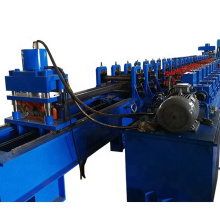

Whole machine of Fully Auto Forming Sheet Making Machine

Production process of Fully Auto Forming Sheet Making Machine

our machines are customized, any part in this working flow can be designed according to your request.

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

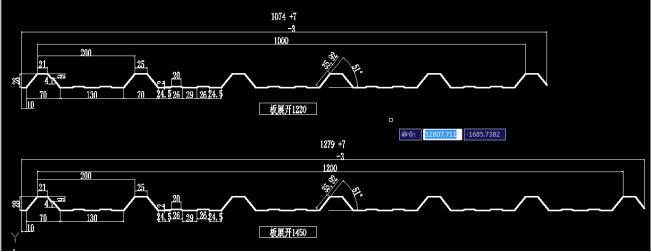

customer drawing profile of Fully Auto Forming Sheet Making Machine

if you have any idea about the profile, contact us and just give us your ideal color steel product.

Our engineer will supply the whole plan for you.

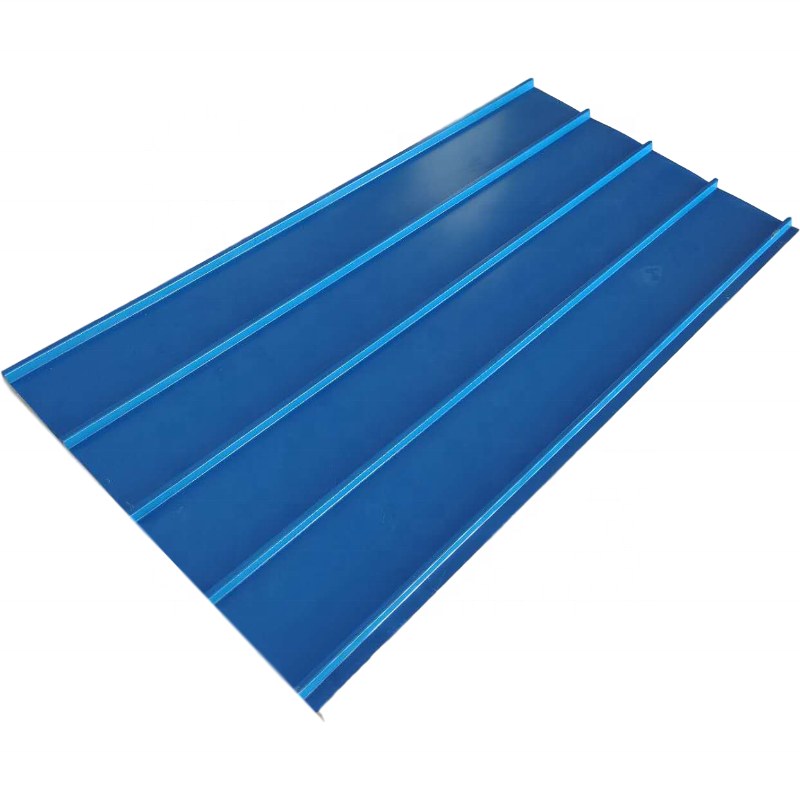

the product of Fully Auto Forming Sheet Making Machine

the product of this machine are welcomed in many field, such as the guarding wall and house roof. Its size and style can be designed .

After cuting , each side of the sheet is neat.

the indentation is clear and smooth. more details please contact us.

Main Forming device of Fully Auto Forming Sheet Making Machine

In order to keep the product shape and precision, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working.

The machine adopts large-scale column structure and independent roller station. Gear box drive stablizes this machine and makes it durable.

Feature: Ensure stability, precision and long lifetime.

there are two kinds of shafts for you. The rollers are made by 45# steel, surface hard chromium plating.

main parameter of Fully Auto Forming Sheet Making Machine

| Length of the main part | About7.2*1.45*1.5m |

| Weight of main part | About 4 t |

| Voltage | 380V/50HZ3Phase (as customer’s request) |

| Roller fixer | large-scale column structure independent roller station |

| Material of rollers | 45# steel, surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ85mm |

| Number of rollers | 16 rollers |

| Main power | 5.5kw |

Coil feeding part of Fully Auto Forming Sheet Making Machine

Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee

that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function,

Cutting device of Fully Auto Forming Sheet Making Machine

The cutting device is made of Cr12 quenched that insure the blade durable and sharp. It is controlled by advanced hydraulic drive. With full automatic punching and cutting after forming,

the machine leaves no distorting or wasting, high level safety factor (include cutting tools, hydraulic tank, and cutter machine)

Controlling device of Fully Auto Forming Sheet Making Machine

Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed withstability, precision and long lifetime. Equipped with movable switch, air break, radiator, transformer & electric leakage

protector for operation convenience and safety.

Components of Fully Auto Forming Sheet Making Machine

| No. | name | Unit | Quantity |

| 1 | 5T decoiler | set | 1 |

| 2 | Guide feeding device | set | 1 |

| 3 | Main roll former | set | 1 |

| 4 | Auto shearing part | set | 1 |

| 5 | PLC control station | set | 1 |

| 6 | Hydraulic oil pump station | set | 1 |

| 7 | Product run-out table | set | 1 |

| 8 | Spare parts | set | 1 |

Spare parts ( for free) of Fully Auto Forming Sheet Making Machine

1. Easy damaged parts: conk 2 pcs, fuse-link 4 pcs;

2. Rubber mat 1 pcs;

3. Bolt spanner 1 pcs

Installation and training:

1.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

2.Without visiting, we will send you user manual and video to teach you to install and operate.

3.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

After Service of Fully Auto Forming Sheet Making Machine

1.One year guarantee for whole machine.

2.24 hours technical support by email or calling

3.If there is any problem found of the machine, we will repair it for free in one year.

1. one 40ft container for loading one set machine with manual decoiler;

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Established in 1996, Zhongtuo Machinery provides a word class metal design, roll forming, fabrication, and project management service to a wide range of national and international engineering projects. ZHONGTUOMachinery is widely regards as Chinese leading special roll forming company, especially in roof/wall sector, now we own three workshops, and already have branch office, warehouse and showroom in India.

At present, our products have been sold to more than 60 countries and areas, achieving good fame.ZHONGTUO is capable and confident with our products that will enable its name in China and be famous in the world.

workshop

Blessed with diligent workers and engineers, we can garantee the machines' quality and delivery time.

Warehouse

our valued customers

Our customers are came from more than 60 countries and areas. We think highly every cooperation and deal with every contact carefully. So that over more than 20 years hard work, our regular customers indicate our strength.

1. Do you have after sales support?

Yes, we are glad to supply advice. Our technicians avaliable across the world.

2.Can you be responsaible for transport?

Yes, just tell me the destination port or adress. We have rich experience in transport.

3.Why your price is higher than others?

As we persist that each factory should put quality at the first place. We spend time and money on developing technology, such as more automatic, more accurate and durable.

4.How long the machine could be made?

Normally speaking, the machine would be finished around 45 days. If you need a machine in hurry, we can shorten that period within 30 days.

5.What should l do if l want to order a machine?

Contact us immediately, we will provide free consultant pre-sales service.

Product Categories : Roof/Wall panel roll forming machine

Premium Related Products