High speed stud and track profile roll forming machine

Product Description

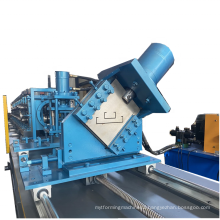

High speed stud and track profile Roll Forming Machine

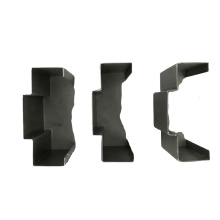

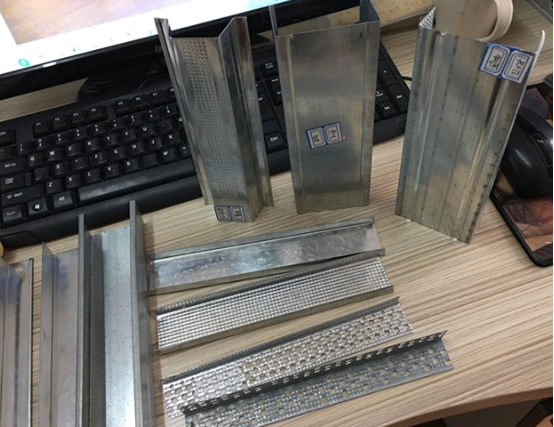

C/U/Omega stud is weldly used in the celling and drywall construction. Compared with cement construction and wooden construction,

Steel frame is more light and durable.Thanks to these advantages, C/U/Omega stud is welcomed in construction field.

Advantages of our High speed stud and track profile roll Forming Machine

1. High speed. Our high speed C/U/Omega stud roll forming machine speed can up t0 80m/min.

Normally, C/U/Omega stud roll forming machine's speed is around 45m/min,

2. High durable. high speed C/U/Omega stud roll forming machine adopts cast steel roller fixer.

3. High automatic. high speed C/U/Omega stud roll forming machine adopts PLC systerm.

User can set production quantity, production speed on control cabinet.

4.Full automatic change sizes by PLC Control,easy to operate and save labor and time.

Packing list of the whole line

| Item | Name | Quantity |

| 1 | Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Hydraulic system | 1 set |

| 4 | Control system | 1 set |

| 5 | Receive table | 1 set |

Working process:

Decoiler--feeding--roll forming--punching(if need holes or logo)--cutting--product table

Technical parameters for the whole production line:

1.Manual decoiler/Hydraulic decoiler

Capacity:1.5T

Coil inner diameter:350-450mm

Coil width:300mm

2.Roll forming machine

1) Machine structure:cast iron roller fixer

2) Main power:7.5KW siemens motor

3) Forming stations:16 stations

4) Way of drive:by gear

5) Diameter of shaft:50mm

6) Max rolling speed: 45m/min

7) Thickness: 0.3-0.8mm or as customer's request

8) Material width:100mm~300mm

9) Material of roller:CR12 with quenched treatment

10) Material of blade mould:Cr12, quenched 58-62

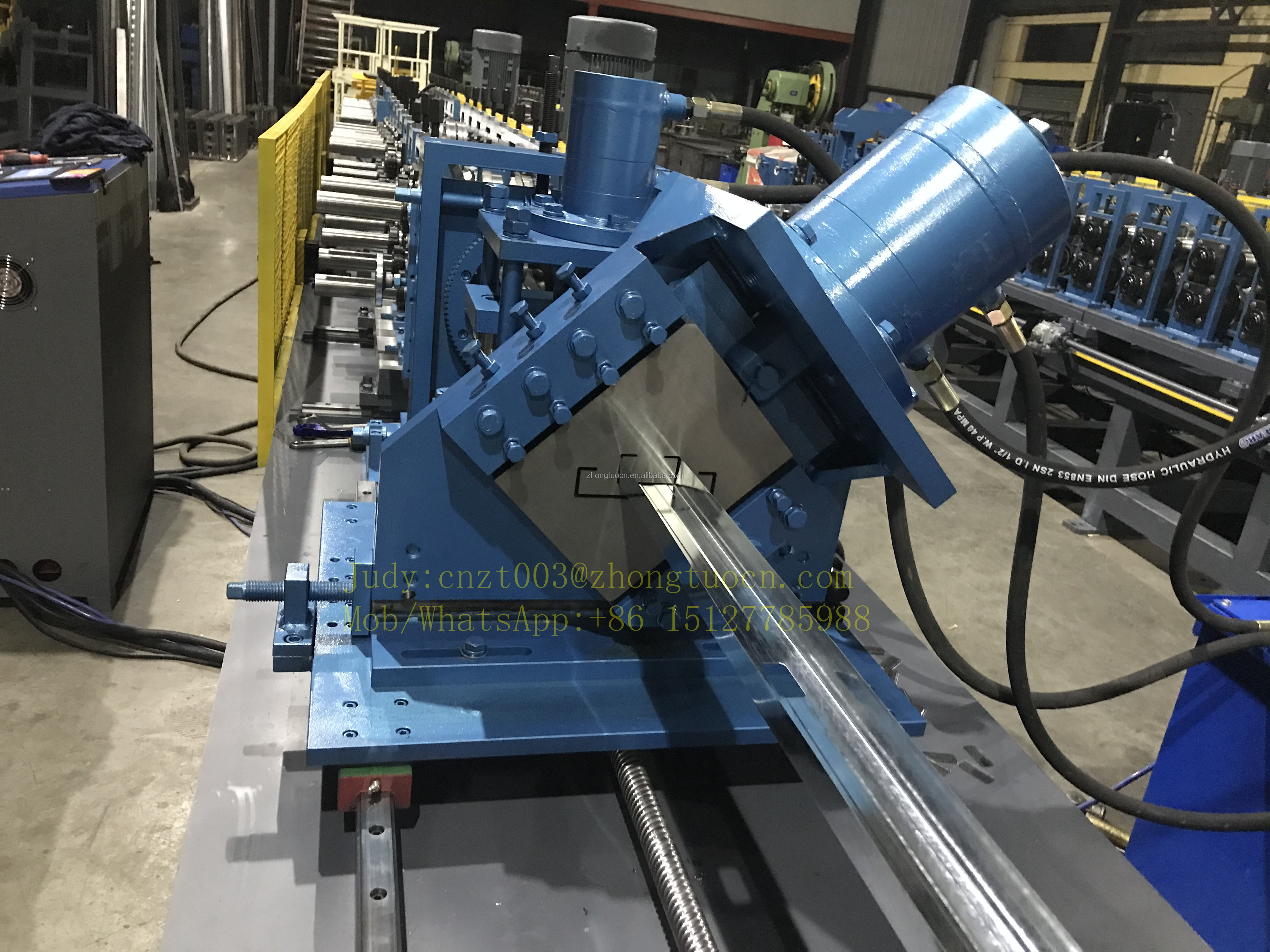

11) Way of cutting:hydraulic mould cutting(flying cut,cut without stop) with SERVO MOTOR DRIVED

12) Length cutting tolerance:+/-1.0mm

13) Electrical requirement:380V,50Hz,3P

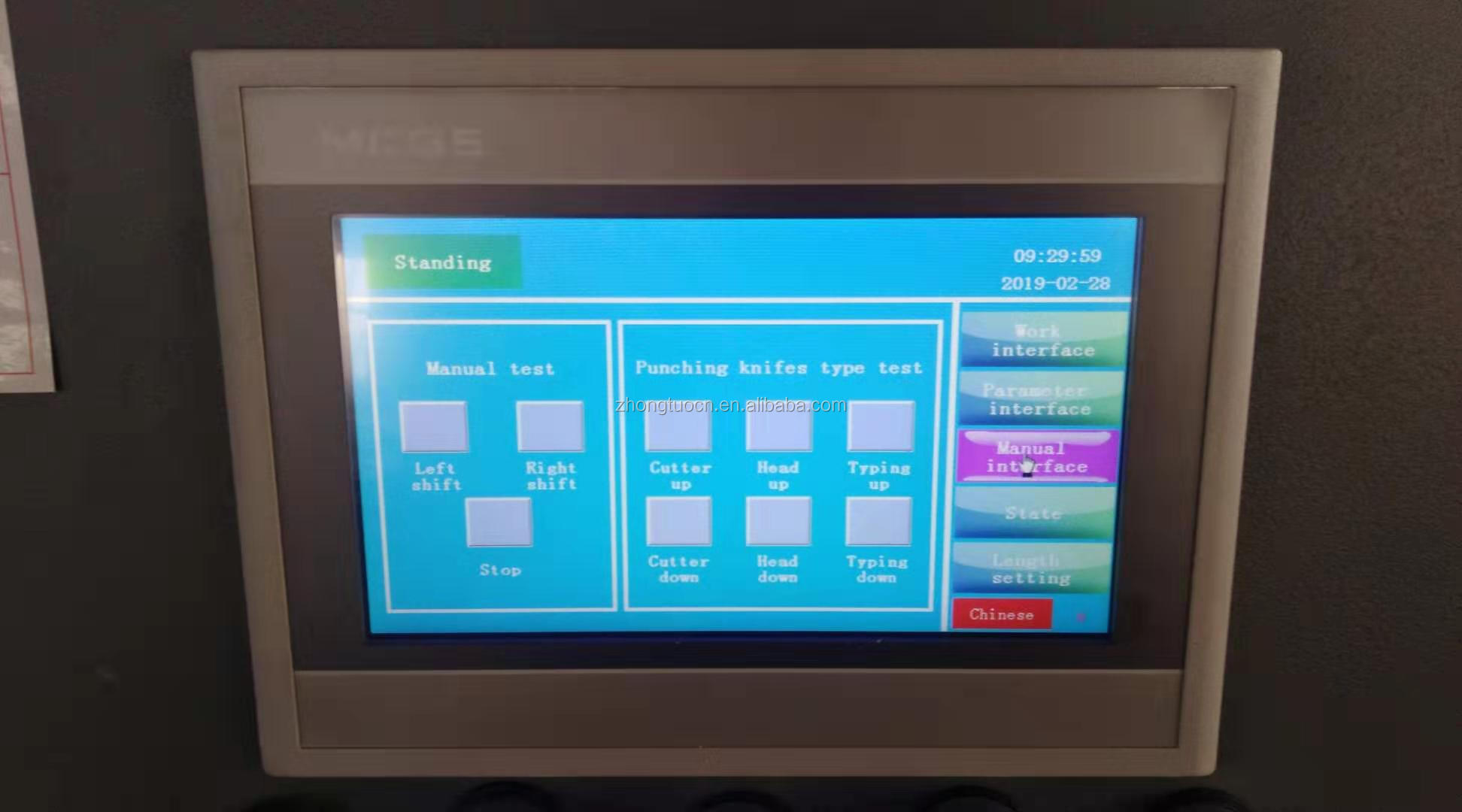

3.Control system

1) Control system:PLC,control to change different sizes,and also from C to U

2) PLC brand:Delta

3) Screen:Touch screen

4) Screen brand:Touch screen

4.Hydraulic system:

1) Hydraulic pressure :16Mpa

2) Hydraulic power:4kw

3) Cooling system:fan cooling

5.Product table

1) Length:3m

2) Manual or automatic

Pictures for reference:

1.Manual decoiler

2.Feeding part

3.Roll Forming Machine

4.Punching holes and stamp logo

5.Cutting system:

6.Control system

7.Hydraulic system

8.Run-out table

1. Quality Control

A. Every parts of machine is examed carefully without any omit.

B. Welcome to our factory to check machine

2. Installation & Training

A. We supply video to teach buyer how to install and operate machine

B. Welcome customers come to our factory, we are glad to teach you face to face.

C. Our technicians could come to customers' factory to install machine

3. After-sale service

A. One year warranty for parts and shipment of parts is free.

B. 24hours*365 days technical support online.

Q: Are you factory or trade company?

A: We are factory and we have a professional engineer team which can design the machine as customers' request

Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available. Our technicians will go to your factory to help you on time.

Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and rich experience about machines and global market. We boast of professional engineer team and after-sale service team.

Q: Once we've bought a machine from you, are you able to supply us with material?

A: We can assist you in finding the appropriate materials to suit your machine

Q: Which is your main market?

A: We supply machine to UK,USA, Austrila and South Korea. Besides, India is our main market, we have Indian sales manager and branch company in India.

Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name.

Product Categories : light steel Keel Roll Forming Machine > light steel Keel Roll Forming Machine

Premium Related Products