Steel Deck Roll Forming Machine Floor Tile Decking Making Machine

Product Description

Steel Deck Roll Forming Machine Floor Tile Decking Making Machine

The floor deck making machine can form the galvanized steel into a customized shape as floor deck used in building’s structure.

The lightness of composite floors considerably reduces dimensions of the load bearing structure. Low in consumption of the materials used and fast to install, they offer construction sites the assurance of very economic solutions. Compatible with steel, concrete, masonry or timber structures, so the steel floor deck is widely used in power plants, power equipment companies, automobile exhibition halls, steel structure workshops,cement warehouses, steel structure offices, airport terminals, railway stations, stadiums, concert halls, grand theaters, large supermarkets,logistics centers, Olympic venues and gymnasium Steel structure.

Adapting to the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short time,and can be used to lay the profiled steel plate on multiple floors, and the flow water construction of the layered concrete slab.

The floor deck making machine can form the the flat sheet into a customized shape, the material of floor deck sheet is galvanized steel.

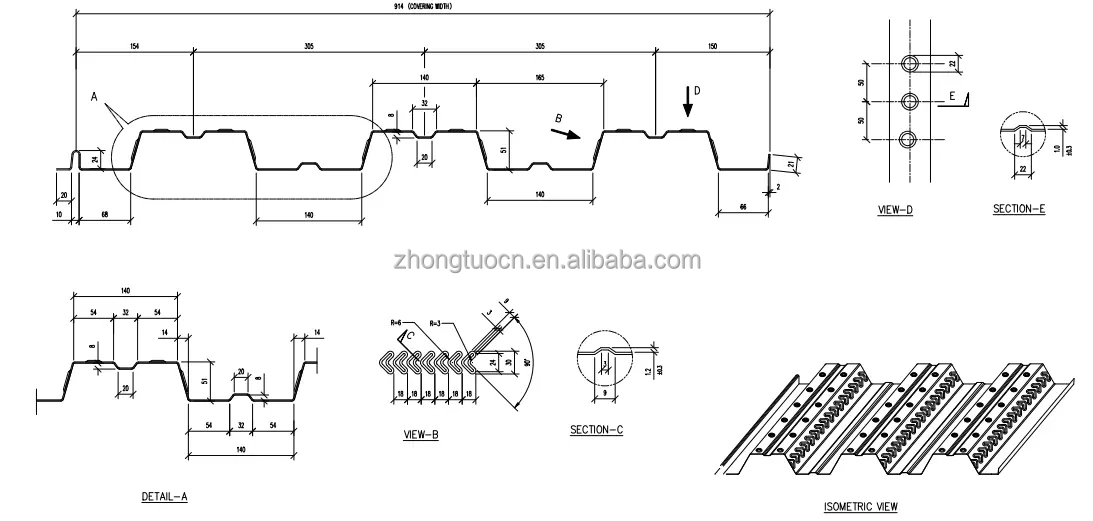

1. The profile drawing of the floor deck making machine

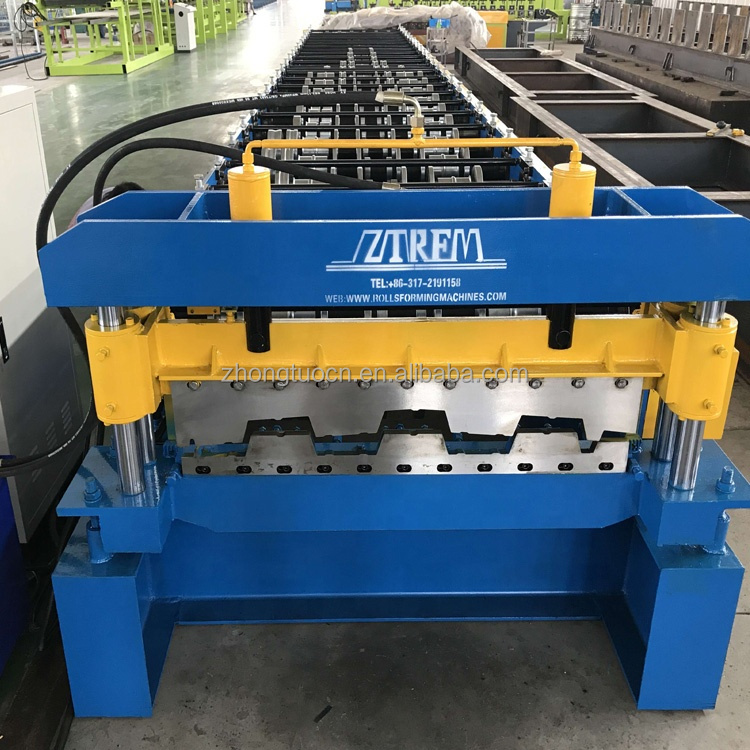

2. Pictures of floor deck making machine and product

Also, we can can learn about how the product looks like after roll forming from floor deck making machine.

Both the machine and product are heavy , especially the floor deck making machine, its weight is more than 10 tons.

3. The working process of floor deck making machine

Uncoiling---feeding material---embossing device---main roll former---hydraulic cutting---run out table

4. The Floor Deck Roll Forming Machine packing list

| Name | Quantity | Remark |

| Decoiler | 1 set | Manual |

| Main roll former | 1 set |

|

| Hydraulic cutting | 1 set |

|

| Hydraulic oil pump | 1 set |

|

| Run out table | 1 set | 3 m length |

5.The design for embossing device of floor deck making machine

6. The main part of the rolling part

There are three carrying rollers on feeding system and plastic rolling wheel in the feeding inlet.It can help the material feed into forming system much easily without scratch.

There are some gears in the left side of machine, the advantage of the gear is obviously:There are 6 gears outside the structure which is on the shafts in the first three stations. The gears connect the upper shaft and down one,so the up and down parts can move in the same speed.Normally, the chains only connect the shaft in the down layer, the upper shafts are moving passively.Since we adopt the gear in the first three stations, both the down layer shaft and upper layer shaft are moving actively.

The main technical parameter of floor deck Roll Forming Machine:

Rolling station number: 28 stations

Driving motor power: 22kw (two motor driving)

Roller material: Cr15

Shaft diameter:95mm

Encoder brand :Omron

7. Hydraulic cutting system

The three cutters on cutting system can prevent the product sheet deformed after cutting, and it's with a very low sounds.

The disadvantage is that will have 2cm material waste for each cutting.

8.Hydraulic station&Control system

The hydraulic oil pump station is equipped with the cooling system. The cooling system can ensure the machine working for a long time without stop and it can also work in a high temperature condition.

The floor deck making machine are control by the PLC .The brand of PLC can be Delta, Siemens, Mitsubishi or other brand.The language of control panel can be English, Spanish, Arabic and others, we can make it according to customers requests.

9.The main feature of floor deck

1).Adapting to the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short time,and can be used to lay the profiled steel plate on multiple floors, and the flow water construction of the layered concrete slab

2). In the use stage, the floor deck is used as the tensile reinforcement of the concrete slab, which also improves the rigidity of the slab

and saves the amount of steel and concrete. The floor deck is generally V-shaped, U-shaped, trapezoidal, and the convex part of the concrete is much less.

Unlike the soil board, it is a flat plate. The floor deck can generally save one-third of the concrete. Now the concrete is expensive.

3).The embossing on the surface of the profiled board creates the greatest bonding force between the floor deck and the concrete,

so that the two form a whole, with stiffening rib, make the floor deck system has high bearing capacity.

4).Under cantilever conditions, the floor slab is only used as a permanent form work.

The length of the cantilever can be determined according to the section characteristics of the floor panel.

In order to prevent the cracking of the cantilever plate, it is necessary to match the negative reinforcement at the support according

to the design of the structural engineer.

You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines.

Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing how to make machines much more automatic, accurate and high quality. We can make sure that our machine could use more than 20 years without any problem. We can provide 2 years free quality assurance

How long the machine could be made?

It usually takes three months.

Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine .It can produce more than 6 kinds of panels.

What is your after sales support?

We are happy to give advice and we also have skilled technicians available across the world.

What can you do if the machine broken?

1.The machine will be tested before shipment with coil, ensure everything is ready

2.We will prepare some spare parts along with the machine, ensure our customer can solve the issue in a shortest time.Both the sale person and technician can give you the service overseas and make training for the workers,the sale person can make translation, so that the installtion and training will be more clear and easily.

Product Categories : Floor Deck Roll Forming Machine

Premium Related Products